Qualicoat Powder Coating Inspection Kit

Qualicoat Powder Coating Inspection Kit Specification

- Accuracy

- Film thickness gauge 2% or 2.5 m

- Equipment Type

- Powder Coating Inspection Kit

- Resolution

- Film thickness gauge: 0.1 m

- Power Supply

- Not required for mechanical tools, UV torch: 2 x AAA batteries (included)

- Specimen Size

- Accepts coated panels up to 150 mm x 100 mm

- Measuring Range

- Varies by instrument, e.g., film thickness gauge: 01500 m

- Automation Grade

- Manual

- Interface Type

- Direct readout, no PC connectivity

- Mounting Type

- Handheld, portable

- Features

- Multi-tool kit, compliant with Qualicoat, includes cross-hatch cutter, gloss meter, film thickness gauge, thermometers, and accessories

- Display Type

- Digital (film thickness gauge), analog (other tools)

- Hardness

- Tool blades: HRC5557

- Application

- Inspection and quality assessment of powder coated surfaces according to Qualicoat standards

- Temperature

- 5C to 40C operating limits

- Number of Specimens

- Suitable for single or multiple panel testing

- Humidity

- 595 % RH (for test environment)

- Response Time

- <1 second (digital gauge)

- Frequency

- Manual use (digital gauge: auto-update)

- Test Range

- Comprehensive kit covers standard Qualicoat tests

- Operating Voltage

- 3V DC for digital gauge, N/A for mechanical tools

- Usage

- On-site or laboratory inspection

- Capacity

- Portable kit (content specific)

- Machine Weight

- Approx. 2.8 kg (excluding case contents)

- Test Speed

- Manual operation, user dependent

- Test Width

- Up to 150 mm sample width

- Test Stroke

- Adjustable, up to 100 mm (cutter)

- Control Mode

- Manual inspection (all tools supplied)

Qualicoat Powder Coating Inspection Kit Trade Information

- Main Export Market(s)

- Asia

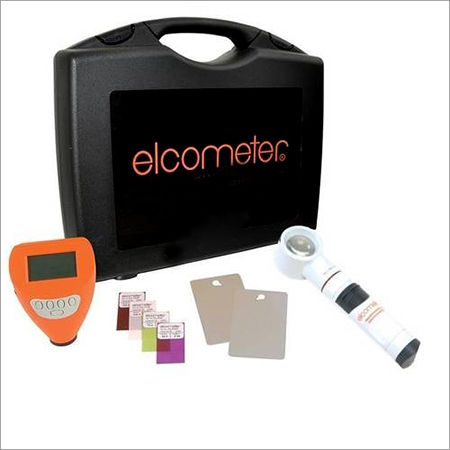

About Qualicoat Powder Coating Inspection Kit

Features

- As a Authorized dealer we are engaged in providing the broad assortment of Elcometer Digital Inspection Kits.

- Elcometer Qualicoat Powder Coating Inspection Kit

- The Qualicoat Organisation brings together the ideals of several national coating associations into one quality label for the powder coating to aluminium architectural applications.

- The aim of Qualicoat is to establish the minimum standard that plant installations, coating materials and finished products which have been powder coated must meet.

- Within this quality label, Qualicoat identifies a range of inspection requirements to be undertaken with regards to the quality control of powder coated products.

- The Elcometer Qualicoat Powder Coating Inspection Kit provides the various test instrumentation required to meet the high standards of this organisation.

Model | Description | Basic | Top |

Elcometer 480 | Statistical Glossmeter: 60 | Model B | Model T |

Elcometer 1506 | Mandrel Bend Tester with 5mm and 8mm (0.20 and 0.31) Mandrels | | |

Elcometer 1615 | Base Unit and Tube Assembly | | |

Elcometer 1615 | Kit B: ISO 6272/2 and BS 6496 | | |

Elcometer 1620 | Manual Cupping Tester with Digital Gauge | | |

Elcometer 215 | Oven Data Logger & Kit | Standard | Top |

Elcometer 415 | FNF Integral Digital Coating Thickness Gauge for smooth surfaces | | |

Elcometer 456 | FNF Separate Digital Coating Thickness Gauge | | Model T |

Elcometer 456 | Standard FNF 1 Probe, 0 - 1500m | | |

Elcometer 1542 | Cross Cut Set 6 x 1, 2, 3mm with ISO or ASTM Adhesive Tape | | |

Comprehensive On-Site Testing

This inspection kit provides the instruments necessary for full-scale quality checks on powder-coated panels. From film thickness to gloss and adhesion assessment, each tool is selected to meet Qualicoat specifications, ensuring robust evaluation directly on-site or in the laboratory. The variety of supplied accessories enhances operational efficiency and minimizes downtime during inspection cycles.

Convenience and Portability

Packaged in a practical and sturdy carrying case, the kit is lightweight (machine weight approx. 2.8 kg) and easy to transport. Its handheld, automation-free design assures seamless manual operation, making it ideal for mobile applications across factories, warehouses, and field sites. With adjustable tools and spare parts included, inspectors can perform fast, repetitive tests without specialized equipment or external power sources.

Accuracy and Compliance

Every instrument includedespecially the digital film thickness gauge and gloss metercomes with a certificate of calibration, ensuring reliable, repeatable measurements. The kit complies with key international standards (EN ISO 2409, ISO 2808, Qualicoat), making it suitable for professional and industrial use. Resolution down to 0.1 m underscores the kits precision.

FAQs of Qualicoat Powder Coating Inspection Kit:

Q: How do I use the Qualicoat Powder Coating Inspection Kit for on-site inspections?

A: Simply unpack the portable case and select the required instrument, such as the film thickness gauge or cross hatch cutter. Follow the supplied instruction manual for each test. No external power is needed for mechanical tools; only the digital gauge and UV torch require batteries (included). Conduct visual, adhesion, gloss, and thickness assessments directly on powder-coated panels.Q: What standards does this inspection kit conform to, and why is this important?

A: The kit is compliant with EN ISO 2409, ISO 2808, and Qualicoat requirements, ensuring all measurements align with internationally recognized testing procedures. This compliance guarantees that surface quality and coating durability meet industry benchmarks, which is essential for accreditation, exports, or contract fulfillment.Q: When should I perform inspections using this kit?

A: Use the inspection kit during the final production stages, after coating curing, or during routine quality checks. Its suitable for both in-process and post-process inspections, supporting regular quality assurance as well as troubleshooting coating defects.Q: Where can the kit be used and what are the environmental requirements?

A: The kit is designed for both laboratory and on-site environments. It operates effectively in temperatures from 5C to 40C and humidity ranging from 5% to 95% RH. Its portable case allows easy transport between locations, making it suitable for use in manufacturing plants, supplier warehouses, or outdoor project sites.Q: What is the process for measuring film thickness with the digital gauge?

A: Place the digital film thickness gauge directly on the coated panel and read the measurement from the devices digital display. Calibration certificates ensure accuracy (2% or 2.5 m), and the devices response time is less than one second, enabling rapid, multiple readings across various spots on the specimen.Q: Which types and sizes of panels can the kit analyze?

A: The kit is optimized for single or multiple powder-coated panel inspections. It accommodates specimens up to 150 mm in width and 100 mm in length, supporting variable sample configurations for both industrial and laboratory purposes.Q: What are the main benefits of using the Qualicoat Powder Coating Inspection Kit?

A: Key benefits include comprehensive, multi-parameter testing in a single kit, efficient portability, compliance with industry standards, and user-friendly, manual operation. It allows inspectors, suppliers, and quality control professionals to quickly evaluate coating performance, saving time and ensuring consistent quality outcomes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Elcometer Category

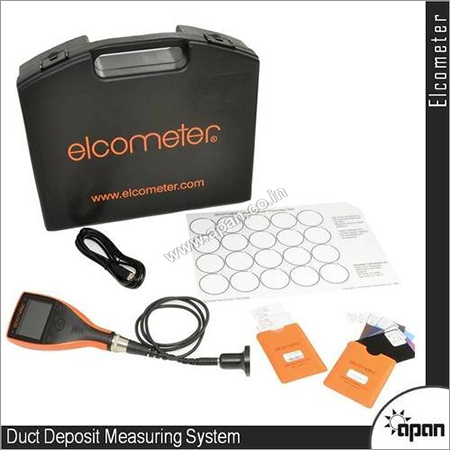

Duct Deposit Measuring System

Usage : HVAC, industrial duct cleanliness verification

Features : Portable, high precision, easy calibration, realtime data output

Application : Measurement of dust, grease or particulate deposit in air ducts

Automation Grade : Semiautomatic

Equipment Type : Portable Duct Deposit Measuring System

Operating Voltage : 220V

Elcometer 3000 Motorized Clemen Unit

Usage : Laboratory scratch resistance testing

Features : Motorized movement, precise control, adjustable speed, robust frame

Application : Scratch resistance testing on coated substrates

Automation Grade : Semiautomatic

Equipment Type : Motorized Clemen Unit

Operating Voltage : 110240V AC

Elcometer Blasting Inspection Kit 2

Usage : Blasting and painting surface preparation inspection

Features : Complete kit for onsite blasting inspection, portable carry case, includes profile gauge, replica tape, dust test kit, salt contamination kit, thermometer, hygrometer

Application : Surface profile, cleanliness, dust, and environmental condition assessment

Automation Grade : Manual

Equipment Type : Blasting Inspection Kit

Operating Voltage : Battery powered instruments (usually 1.5V or 9V battery)

Elcometer Blasting Inspection Kit

Usage : Onsite Inspection and Measurement

Features : Comprehensive Kit for Surface Profile, Blast Cleaning & Dust Assessment

Application : Surface Preparation and Blasting Inspection

Automation Grade : Manual

Equipment Type : Blasting Inspection Kit

Operating Voltage : N/A (Mechanical)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry