Magnetic Brinell Rockwell Hardness Tester

Magnetic Brinell Rockwell Hardness Tester Specification

- Operating Voltage

- 220V AC

- Application

- For testing hardness of ferrous and non-ferrous metals, including large or heavy workpieces

- Measuring Range

- 8650 HB (Brinell), 2070 HR (Rockwell)

- Mounting Type

- Magnetic/Portable

- Temperature

- 10C35C

- Equipment Type

- Magnetic Brinell Rockwell Hardness Tester

- Display Type

- Analog Dial / Pointer

- Frequency

- 50Hz

- Humidity

- 85% RH

- Features

- Portable, Magnetic Base, Dual Scale (Brinell & Rockwell), Robust Construction

- Number of Specimens

- Single Specimen

- Interface Type

- Manual

- Accuracy

- 1% of test load

- Port Size

- Standard

- Resolution

- 0.1 HR / HB

- Max Height

- Approx. 350 mm

- Test Range

- Brinell: 8650 HBW, Rockwell: 2088 HRA, 20100 HRB, 2070 HRC

- Specimen Size

- Up to 200 mm diameter

- Power Supply

- AC 220V, 50Hz

- Hardness

- Brinell & Rockwell Scales

- Response Time

- Immediate

- Automation Grade

- Manual

- Usage

- Industrial Hardness Testing

- Capacity

- Max Load 3000 kgf

- Machine Weight

- Approx. 50 kg

- Test Speed

- Standard

- Test Width

- Up to 200 mm

- Test Stroke

- Up to 100 mm

- Control Mode

- Manual

- Operation

- Lever Operated

- Calibration

- Factory Calibrated

- Magnetic Base Attraction Force

- 500 kgf

- Finish

- Powder Coated

- Body Material

- Hardened Steel Construction

- Hardness Test Method

- Brinell and Rockwell Methods

- Indenter Type

- Steel Ball Indenter / Diamond Cone

- Accessories Included

- Indenter, Test Blocks, Operating Manual

Magnetic Brinell Rockwell Hardness Tester Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

About Magnetic Brinell Rockwell Hardness Tester

Versatile Applications & Exceptional Material Quality

The Magnetic Brinell Rockwell Hardness Tester excels in testing ferrous and non-ferrous metals on diverse application surfaces, including large plant equipment and heavy industrial components. Its impressive material featurehardened steel constructionensures longevity and resistance to wear. With dual-scale capacity and a portable magnetic mounting, it reliably assesses hardness on site or in the plant, adapting to wide-ranging material and diameter sizes up to 200 mm with maximum effectiveness.

Reliable Supply Abilities & Domestic Market Support

Our supply ability ensures prompt availability for bulk or single-unit purchase orders, supported by an extensive distribution network throughout Indias main domestic market. The asking price is competitive, with transparent terms for advanced purchase, and freight options tailored to your requirements. Payment terms are flexible, accommodating bank transfers and standard industry practices, guaranteeing seamless order processing from inquiry to delivery for trustworthy, long-term supply partnerships.

FAQs of Magnetic Brinell Rockwell Hardness Tester:

Q: How does the magnetic base of the hardness tester benefit on-site testing?

A: The powerful magnetic base provides stable mounting directly on large or irregular workpieces, removing the need for additional fixtures. This ensures accurate, repeatable hardness measurements even in challenging plant or field environments.Q: What materials and hardness ranges can be tested with this device?

A: It is suitable for both ferrous and non-ferrous metals, supporting Brinell (8650 HBW) and Rockwell scales (2088 HRA, 20100 HRB, 2070 HRC), enabling extensive use across diverse industrial applications.Q: When is advance purchase recommended for this tester?

A: Due to limited stock and high demand, advance purchase is recommended, particularly for large orders or time-sensitive projects, to secure prompt supply and delivery.Q: Where can this hardness tester be applied within a manufacturing plant?

A: It is designed for use on the shop floor, quality control labs, and maintenance sections. Its portability allows for hardness assessment on installed or heavy plant machinery without dismantling.Q: What is the process for calibration and maintenance of the tester?

A: Each unit is factory calibrated for immediate use. Routine maintenance involves checking the indenter, cleaning the magnetic base, and periodic verification using the supplied test blocks to ensure sustained accuracy.Q: How does the asking price and payment procedure work for bulk orders?

A: The asking price is provided upon inquiry, and bulk or distributor orders require a purchase order. Payment terms are flexible, with options like bank transfer, and freight arrangements are discussed per client requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Portable Hardness Tester ASTM A956

Usage : Industrial/Field Hardness Testing

Application : Metallic material hardness measurement

Specimen Size : Minimum weight 0.1 kg (with support ring)

Hardness : Supports HL, HB, HRB, HRC, HV, HS scales

Response Time : <1 second

Automation Grade : SemiAutomatic

Vickers Hardness Measuring System

Usage : Metallurgical, Research Labs, Industrial Testing

Application : Material Hardness Testing

Specimen Size : Maximum Height 70 mm

Hardness : Vickers (HV)

Response Time : Instantaneous

Automation Grade : SemiAutomatic

Digital Rockwell & Superficial Hardness Tester

Usage : Hardness Testing of Metals

Application : Metallurgy, Quality Control, Laboratory

Specimen Size : Max Height 230 mm, Depth 150 mm

Hardness : Rockwell, Superficial Rockwell

Response Time : 1 sec

Automation Grade : SemiAutomatic

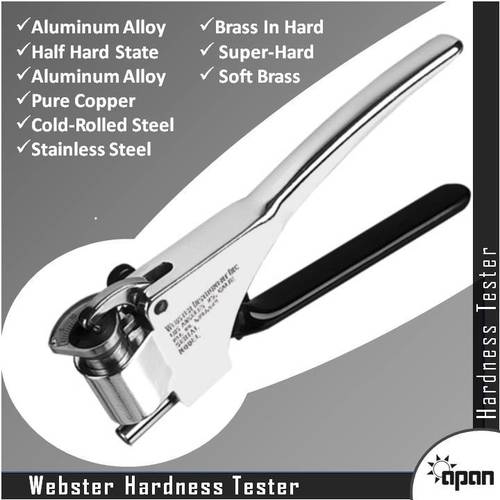

Webster Hardness Tester

Usage : Industrial, QA/QC, Laboratory

Application : Onsite rapid hardness testing of aluminum alloys, copper, brass etc.

Specimen Size : Up to 13 mm thickness, standard jaw length

Hardness : Webster Scale (HRE)

Response Time : Immediate

Automation Grade : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry