Webster Hardness Tester

Webster Hardness Tester Specification

- Humidity

- 85% RH

- Features

- Portable, Direct Reading, No Power Needed

- Display Type

- Analog dial

- Equipment Type

- Portable Handheld Hardness Tester

- Mounting Type

- Handheld

- Automation Grade

- Manual

- Power Supply

- Not Required (Handheld, mechanical)

- Accuracy

- 1 HRE

- Port Size

- Standard jaw width

- Hardness

- Webster Scale (HRE)

- Response Time

- Immediate

- Test Range

- Material dependent; typical: 25-110 HRE (Webster Hardness)

- Max Height

- Suitable for profiles up to 13 mm thickness

- Application

- On-site rapid hardness testing of aluminum alloys, copper, brass etc.

- Number of Specimens

- Single point measurement

- Specimen Size

- Up to 13 mm thickness, standard jaw length

- Resolution

- 1 HRE

- Measuring Range

- 25-110 HRE (Webster)

- Temperature

- 0~40C

- Usage

- Industrial, QA/QC, Laboratory

- Capacity

- Applicable for aluminum profiles, pipes, plates

- Machine Weight

- 0.5 kg

- Test Speed

- Manual operation, instantaneous reading

- Test Width

- Maximum 13 mm (sample edge distance)

- Test Stroke

- 2 mm

- Control Mode

- Manual

Webster Hardness Tester Trade Information

- Main Export Market(s)

- Asia

About Webster Hardness Tester

Webster Hardness Tester is Portable, fast, accurate hardness gage available in several models for testing materials such as aluminum, brass, copper and mild steel. Quickly identify tempers. Tests a variety of shapes that other testers cannot check: Extrusions, Tubing and Flat Stock.

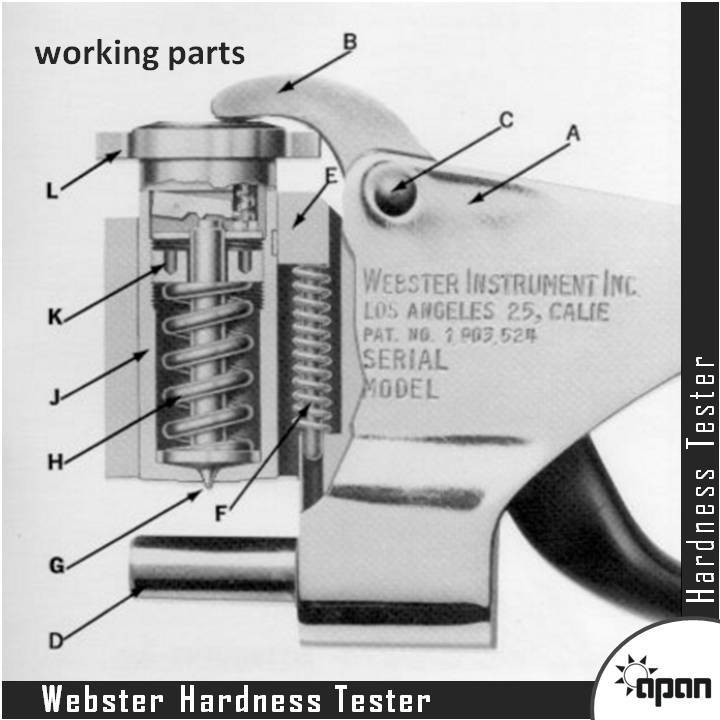

All testers operate in the same manner but differ only in penetrator design, type of load spring and hardness ranges. The principle of operation is simple. The work to be tested is placed between the anvil and the penetrator. Pressure is then put to the handles until "bottom" is felt at which time the dial indicator is read.

Applications for Webster Hardness Testers are:

- Identifies heat-treated from nonheat-treated parts.

- Provides correlation between a bench mounted hardness tester and the production line.

- Segregates materials in stock.

- Differentiates between soft or work-hardened material.

- Identifies parts made from improper or substandard alloys.

- Checks for proper heat-treatment response.

- Useful in conjunction with stationary laboratory hardness testers. Gives a rapid 100% check on parts which would consume many man hours with slower operating test equipment.

- Can be used on assemblies that cannot be brought to the labs.

Webster Hardness Testers Feature:

- One hand operation and portability.

- Round 3/8 inch diameter anvil permits testing a great variety of shapes.

- Simple operation permits readings independent of the operator's skill.

- Test is made by simply putting pressure to the handles until "bottom" is felt.

- Easy-to-read dial indicator with 20 graduations permits use of the tester as "go" and "no-go" gauge.

- Standard hardness gauge tests materials up to 1/4 inch in thickness.

- Increased capacities available up to 1 inch.

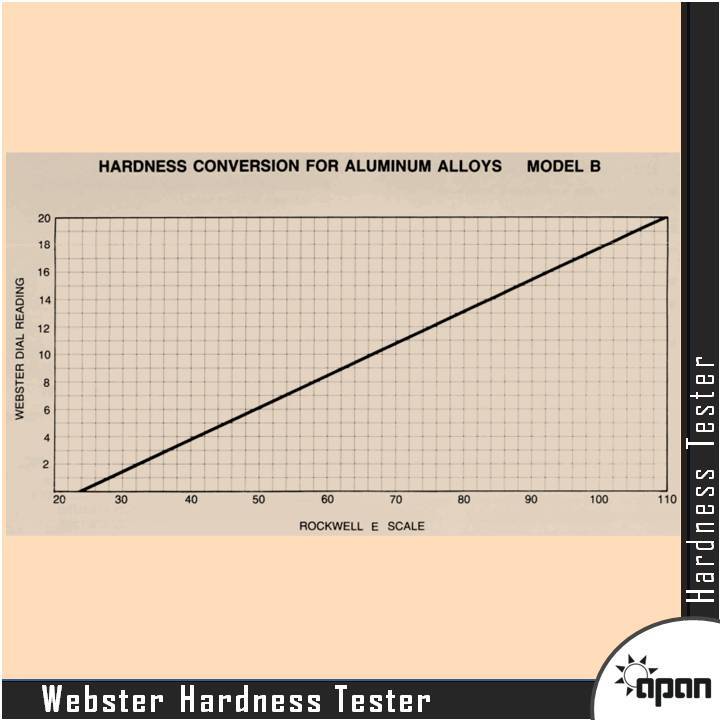

The Model B Tester is designed to cover the hardness of aluminum alloys from the 1100 to the 7075 series. The 20 graduations on the Webster dial indicator covers the range between 25 and 110 on the Rockwell E Scale.

The Model B-75 Tester was developed to obtain more sensitive response to slight changes in the upper range of hardness covered by the Model B. This sensitivity is particularly useful in testing mild steel and the stronger aluminum alloys. For brass the B-75 covers the range from annealed to full-hard. This added sensitivity is accomplished by incorporating a penetrator of slightly different contour and a heavier load spring than used in the Model B. The 20 graduations on the Webster dial indicator covers the range between 20 and 100 on

the Rockwell B Scale. The Model BB-75 Tester was developed to answer the need of certain industries for a method of rapidly testing the hardness of electro-deposited copper and copper in the low hardness range. The B-75 penetrator is used to give sensitivity and the Model B load spring is employed to give light pressures. This combination allows the user to test the soft range of many common materials.

Specification

| Testing Range | Specimen Size/mm | Application |

| 25-110 HRE 58-131 HV | Thickness 0.4-6 Inner diameter>10 | Aluminum alloy |

| Thickness 0.4-13 Inner diameter>10 | ||

| Thickness 0.4-8 Inner diameter>6 | ||

| 63-105 HRF | Thickness 0.4-6 Inner diameter>10 | Brass in hard or half hard state

|

| Thickness 0.4-8 Inner diameter>6 | ||

| 18-100 HRE | Thickness 0.4-6 Inner diameter>10 | Soft brass

|

| Thickness 0.4-8 Inner diameter>6 | ||

| 50-92 HRB | Thickness 0.4-6 Inner diameter>10 | Cold-rolled steel sheet |

Portable and Efficient Hardness Testing

The Webster Hardness Tester is specifically engineered for on-the-spot measurement of material hardness, enabling instant evaluation without the need for laboratory facilities or external power. With manual operation and direct analog scale reading, obtaining and interpreting test results is remarkably quick and straightforward. The portable design and included carrying box offer practical mobility for use in various industrial and field environments.

Versatile Application for Metals

Compatible with a range of metalsincluding aluminum, copper, and brassthe tester accommodates both flat and tubular specimens up to 13 mm thick. Its adaptability ensures reliable performance for profiles, pipes, and plates, making it ideal for distributors, exporters, and industrial labs requiring rapid, single-point hardness measurement in compliance with global standards like GB/T231.2 and ASTM B647.

FAQs of Webster Hardness Tester:

Q: How is the Webster Hardness Tester calibrated before use?

A: The tester is calibrated using a standard test block supplied with the instrument. This ensures consistent accuracy across all measurements and meets the requirements of GB/T231.2 and ASTM B647 standards.Q: What types of specimens can be tested with this device?

A: The Webster Hardness Tester is suitable for flat and tubular samples, such as aluminum profiles, pipes, and plates, with a maximum thickness of 13 mm and a test stroke of 2 mm.Q: When should I use this tester instead of laboratory methods?

A: Use this tester for on-site rapid assessments when immediate results are neededespecially during production, inspection, or quality controlwithout the need for laboratory equipment or electricity.Q: Where can this device be practically used?

A: This handheld tester is ideal for use on the factory floor, in the warehouse, during field inspections, or any setting where quick, reliable hardness readings of metal samples are essential.Q: What is the process to perform a hardness test with this instrument?

A: Simply position the specimen in the jaws, manually operate the lever to engage the hardened steel indenter, and read the value directly from the analog scale. The response is immediate, enabling high-efficiency testing.Q: How does this tester benefit quality assurance processes?

A: Its portability and instant, direct readings allow for rapid screening of materials, enabling quick quality checks and minimizing downtime in production or inspection environments.Q: Is ongoing maintenance complicated for this equipment?

A: Maintenance is straightforward and minimal. Aside from occasional calibration checks using the provided test block, the tester generally requires little upkeep, and after-sales service is available if needed.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Hydraulic Brinell Hardness Tester

Display Type : Analog Dial/Scale

Features : Robust construction, reliable hydraulic loading, user friendly operation

Control Mode : Manual Hydraulic

Test Stroke : 100 mm

Humidity : Up to 90% RH, noncondensing

Power Supply : 230 V, 50 Hz, Single Phase

Digital Rockwell & Superficial Hardness Tester

Display Type : Digital LCD

Features : Digital Display, Automatic Loading/Unloading, Memory Function

Control Mode : Digital

Test Stroke : Vertical, 150 mm

Humidity : 85% RH

Power Supply : 220V AC, 50Hz

Tablet Hardness Tester

Display Type : Digital/LCD

Features : Portable, easytooperate, robust construction

Control Mode : Manual

Test Stroke : 020 mm

Humidity : 85% RH

Power Supply : 230 V AC, 50 Hz

Portable Hardness Tester

Display Type : LCD digital display

Features : Memory function, backlit display

Control Mode : Manual

Test Stroke : 20 mm

Humidity : 90% RH

Power Supply : 2 x AA Batteries

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry