Manual Digital Rockwell Hardness Tester

Manual Digital Rockwell Hardness Tester Specification

- Automation Grade

- Manual

- Application

- Hardness testing of metals and alloys

- Hardness

- Rockwell C (HRC) scale

- Max Height

- 170 mm

- Humidity

- 80%

- Response Time

- Instantaneous

- Equipment Type

- Manual Digital Rockwell Hardness Tester

- Temperature

- 10C ~ 40C

- Number of Specimens

- Single specimen

- Features

- High precision, easy operation, digital readout

- Measuring Range

- 20~100 HRC (Rockwell C)

- Frequency

- 50 Hz

- Power Supply

- 220 V / 50 Hz

- Interface Type

- Panel buttons

- Test Range

- 20~100 HRC

- Mounting Type

- Bench top

- Operating Voltage

- 220 V

- Resolution

- 0.1 HRC

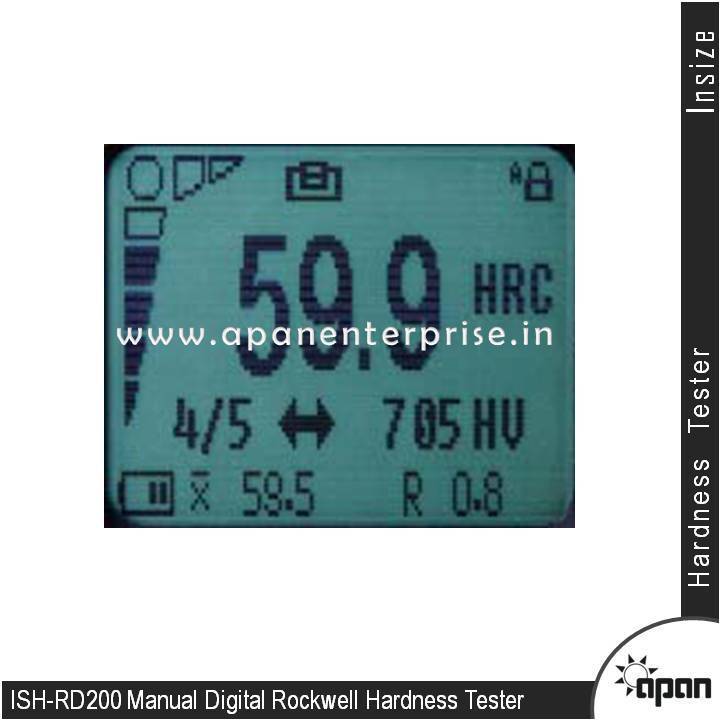

- Display Type

- Digital LCD

- Specimen Size

- Height 170 mm, Depth 135 mm

- Accuracy

- 1%

- Usage

- Industrial, Laboratory

- Capacity

- Maximum 150 kgf

- Machine Weight

- 80 kg

- Test Speed

- Standard

- Test Width

- 160 mm

- Test Stroke

- 50 mm

- Control Mode

- Manual and Digital

- Data Output

- RS232C (optional)

- Operating Environment

- Indoor use, clean workspace

- Main Test Forces

- 60, 100, 150 kgf

- Dwell Time

- 2~60 seconds adjustable

- Compliant Standards

- Conforms to ISO 6508, ASTM E18

- Indenter Type

- Diamond cone and steel ball

- Preliminary Test Force

- 10 kgf

- Display Language

- English

- Finish

- Powder coated anti-corrosive body

- Accessories Supplied

- Calibration block, anvil, user manual

- Dimensions (L×W×H)

- 520 × 240 × 700 mm

Manual Digital Rockwell Hardness Tester Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

About Manual Digital Rockwell Hardness Tester

Our company is looked upon as the foremost company in this industry, engaged in offering supreme grade Manual Digital Rockwell Hardness Tester. The equipment is extensively used to test the hardness of various metals and alloys in industries. We are offering this equipment to clients in different specifications in order to cater their requirements. Manual Digital Rockwell Hardness Tester is used in varied industries for testing the metals and alloys.

Features:

- High impact strength

- User friendly design

- Long working life

Versatile and Precise Hardness Testing

This Rockwell Hardness Tester offers robust versatility for various metals and alloys, providing high accuracy and stability. Its digital LCD display delivers instant results across a measuring range of 20100 HRC. With adjustable dwell time and selectable test forces up to 150 kgf, its suitable for a range of industrial and laboratory applications. The powder-coated finish assures corrosion resistance, extending instrument durability in diverse environments.

User-Friendly Operation and Connectivity

Equipped with both manual and digital control modes, the tester supports straightforward operation via intuitive panel buttons. The digital interface, complemented by an optional RS232C port, enables efficient data output and documentation. Supplied calibration blocks and an anvil make calibration and setup efficient, while multilingual guidance in English simplifies use. This machine is bench-mounted, requiring standard indoor conditions for optimal performance.

Compliance and Safety Commitment

Adhering strictly to ISO 6508 and ASTM E18 standards, this tester guarantees dependable, standardized results with every test. Features such as adjustable dwell time (260 seconds) and anti-corrosive powder coating safeguard user and equipment alike. The machine operates safely between 10C and 40C and humidity below 80%, ensuring long-term reliability for all users.

FAQs of Manual Digital Rockwell Hardness Tester:

Q: How do I operate the Manual Digital Rockwell Hardness Tester for a hardness test?

A: To perform a test, place a single specimen (maximum height 170 mm, depth 135 mm) on the anvil, select the desired dwell time (260 seconds), set the preliminary (10 kgf) and main test force (60, 100, or 150 kgf), and initiate the test using the panel buttons. The result is instantly displayed on the digital LCD.Q: What materials can this Rockwell Hardness Tester measure?

A: This instrument is suitable for testing the hardness of metals and alloys within the 20~100 HRC (Rockwell C) measuring range, making it ideal for industrial and laboratory quality control of a wide variety of metallic samples.Q: When is calibration required and what accessories are included?

A: Calibration should be conducted regularly, especially before critical testing. The tester is supplied with a calibration block and anvil, ensuring straightforward and accurate calibration every time, as outlined in the user manual.Q: Where should the hardness tester be installed and operated?

A: The machine is intended for indoor use on a stable bench surface in a clean, dry workspace. Optimal performance is achieved at ambient temperatures ranging from 10C to 40C with humidity at or below 80%.Q: What is the process for exporting or distributing this hardness tester in India?

A: As a distributor, exporter, importer, supplier, trader, or wholesaler in India, you must comply with local regulations and standards. The products conformity to ISO 6508 and ASTM E18 simplifies certification for industrial and laboratory clients.Q: How does the digital data output feature enhance usage?

A: With the optional RS232C data output, users can efficiently transfer and document test results, facilitating data management and integration with laboratory information systems for enhanced process traceability and quality assurance.Q: What are the main benefits of choosing this manual digital Rockwell hardness tester?

A: Key benefits include high measurement accuracy (1%), intuitive operation, robust construction, instant digital readout, and compliance with international standards, making it a dependable solution for both industrial and laboratory applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Digital Compression Testing Machine

Application : Compression Strength Testing for Materials

Usage : Material Testing

Control Mode : Digital, Automatic

Automation Grade : Automatic

Hardness : Heavy Duty Cast Iron

Humidity : Up to 90% RH

Magnetic Rockwell Hardness Tester

Application : For hardness testing of ferromagnetic materials

Usage : Onsite or Laboratory Hardness Testing

Control Mode : Manual

Automation Grade : Manual

Hardness : Rockwell C (HRC) Scale

Humidity : 85% RH

Leeb Hardness Tester

Application : Testing the hardness of steel, cast steel, alloy tool steel, stainless steel, gray cast iron, nodular cast iron, cast aluminium, brass, bronze, copper, and other materials

Usage : Nondestructive hardness testing of metals

Control Mode : Manual

Automation Grade : Manual

Hardness : Leeb hardness (HL), can convert to HRC, HB, HV, HS, etc.

Humidity : 90% RH

Ultrasonic Hardness Tester

Application : Metals Hardness Measurement

Usage : Nondestructive Testing

Control Mode : Digital Control

Automation Grade : Manual

Hardness : Rockwell, Vickers, Brinell, Shore, Leeb

Humidity : 90% RH (noncondensing)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry