Leeb Hardness Tester

Leeb Hardness Tester Specification

- Humidity

- 90% RH

- Number of Specimens

- Single or multiple, depending on application

- Accuracy

- 6 HL (0.5% at 800 HL)

- Port Size

- USB/Serial Port (for data transfer)

- Application

- Testing the hardness of steel, cast steel, alloy tool steel, stainless steel, gray cast iron, nodular cast iron, cast aluminium, brass, bronze, copper, and other materials

- Measuring Range

- 170-960 HL (Leeb) / Converts to HRC, HB, HV, HS, and others

- Operating Voltage

- 3 V (2 x AA batteries)

- Temperature

- 0C to 40C

- Response Time

- Immediate (real-time display)

- Mounting Type

- Handheld

- Features

- Portable, Memory storage, Backlight display, Conversion to multiple hardness scales, USB data transfer

- Power Supply

- 2 x AA (1.5V) batteries

- Test Range

- 170-960 HL (Leeb hardness)

- Display Type

- LCD digital display

- Resolution

- 1 HL

- Interface Type

- USB/Serial

- Hardness

- Leeb hardness (HL), can convert to HRC, HB, HV, HS, etc.

- Specimen Size

- Minimum mass: 2 kg (with coupling), Minimum thickness: 3 mm

- Automation Grade

- Manual

- Equipment Type

- Leeb Hardness Tester

- Usage

- Non-destructive hardness testing of metals

- Capacity

- Supports up to 500 groups (average of 32 readings per group)

- Machine Weight

- Approximately 350 g (including probe)

- Test Speed

- Standard impact speed: 5 m/s

- Test Stroke

- Variable by attachment, standard 11 mm

- Control Mode

- Manual

Leeb Hardness Tester Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Certifications

- ASTM A956, GB/T 17394-1998

About Leeb Hardness Tester

As a Authorized dealer we are engaged in providing the broad assortment of "Hardness Tester" includes table top and Portable type. leeb hardness means the ratio of the impacting velocity and the rebounding velocity of the impact body when the spherically test tip is located 1 mm above the testing surface.

The impact body, which is equipped with tungsten carbide, impact velocities are measured at the 1mm point from the work piece in the following way: the integrated permanent magnet will produce directly proportional voltage with the impact velocity.

Feature

The impact body, which is equipped with tungsten carbide, impact velocities are measured at the 1mm point from the work piece in the following way: the integrated permanent magnet will produce directly proportional voltage with the impact velocity.

Feature

- Pen type design

- Self contained (Impact device and display integrated): no cables.

- The unique large-screen OLED color display (1.77-inch OLED Screen)

- Interchangeable D impact device (standard) /DL impact device (optional) can achieve one unit dual use; can be used in the restricted area measurement.

- With battery compartment, battery can be replaced. Using standard AAA Lithum battery.

- Highly accuracy in any impact direction (360 degree), automatically identify impact direction and gravity compensation

- Easy Operation, the four soft keys above the screen achieve the various functions.

- Display Type : 1.77 inch OLED with resolution 160x128 pixels

- Hardness Scale : HL, HB, HRB, HRC, HV, HS. b.

- Measuring Range : HLD (200-960) HRC(19.8-68.5) HB(30-651) HV(80-976) HS(26.4-99.5) HRB(13.5-100).b.(375-2639)

- Impact Device : D type impact device (Standard); Optional DL type impact device

- Accuracy : 6HLD (HLD=800), Repeatability < 6HLD (HLD=800)

- Measuring direction : 360 degree by manual setting

- Material : Steel & Cast Steel, Stainless Steel, GC IRON, NC IRON, Cast Aluminum alloy, Macht metal, Copper-tin alloy, Brass, Forged Steel

- Resolution : 1HL, 1HV, 1HB, 0.1HRB, 0.1HRC, 0.1HS

- Calibration : Automatic

- Memory : 1000 groups ,each group include 6 testing result and 1 average value

- Communication : USB port, used for recharging and data transmission

- Software : DataVIEW Software for transmission, storage, and printing

- Power : AAA Polymer lithium battery , Capacity of 600 MA/H, voltage:3.7 V, warning under low voltage

- Instrument Shut-off : AUTO OFF after 3 minutes of inactivity

- Temperature : -10 to +50 Degrees Celsius

- Net Weight : 110g with D type impact device,125g with DL type impact device

- Size : 150mm x 46mm x 23mm

- Standard : GB/T 17394-1998, ASTM A956

Versatile Material Testing

This Leeb Hardness Tester is engineered for versatility, allowing precise measurements across an array of metals, including ferrous and non-ferrous alloys. Its ability to convert Leeb hardness readings to multiple standard hardness scales makes it suitable for quality assurance in manufacturing, metalworking, and research environments.

User-Friendly Design and Operation

Equipped with a clear LCD digital display, user calibration, and language options in English and Chinese, this device features straightforward manual control. Weighing only 350 g and powered by standard AA batteries, it ensures portability for field or factory use, making it well-suited to busy testing routines.

Reliable Data Management

With its robust storage capacity for up to 500 individual results or grouped sets, the device simplifies recordkeeping. Statistical evaluation tools (average, maximum, minimum, and count) and high/low hardness limit alarms aid in data analysis, while USB/serial connectivity streamlines exporting reports for further inspection or documentation.

FAQs of Leeb Hardness Tester:

Q: How does the Leeb Hardness Tester operate for measuring metal hardness?

A: The device employs an Impact Device Type D to determine Leeb hardness by striking the test material at a standard speed (5 m/s). The rebound velocity is measured, and the corresponding hardness value is displayed instantly on the LCD screen. This non-destructive method allows rapid and repeatable testing.Q: What types of materials can be tested with this hardness tester?

A: This instrument can measure the hardness of various metals, such as steel, cast steel, alloy tool steel, stainless steel, gray cast iron, nodular cast iron, cast aluminium, brass, bronze, copper, and similar materials. It supports a wide Leeb range of 170960 HL and converts readings to other scales (HRC, HB, HV, HS).Q: When should user calibration be performed, and how is it done?

A: User calibration is recommended before initial use and periodically, especially if the device is used for critical applications or after extended storage. Calibration is performed by following the devices menu prompts, using a reference material with known hardness to ensure measurement accuracy.Q: Where can testing be carried out using this device?

A: Thanks to its lightweight and portable design, the tester is suitable for use in field environments, production sites, workshops, or laboratories. Its battery-powered operation and compact size (approximately 350 g) enable convenient on-site or in-situ hardness evaluations.Q: What is the process for storing and transferring data?

A: The tester can store up to 500 measurement results or group averages, each with a maximum of 32 readings per group. Data can be reviewed on the device and exported via USB or serial port to a computer for further analysis or documentation needs.Q: How does the alarm function enhance usability during testing?

A: High/Low hardness limit alarms can be preset, alerting the operator when a reading falls outside the defined range. This helps ensure quality standards are consistently met, reducing errors and improving process efficiency.Q: What are the main benefits of using this hardness tester compared to traditional methods?

A: The main advantages include non-destructive testing, fast and immediate results, flexibility in converting to multiple hardness scales, extensive memory storage, easy data transfer, and ease of useideal for both routine and critical hardness assessments in various industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Material Testing Category

Automatic Digital Rockwell Hardness Tester

Humidity : 85% RH

Number of Specimens : Multiple consecutive tests possible

Accuracy : 1 HR

Test Speed : 50~60 tests/hour

Control Mode : Automatic digital

Response Time : Instantaneous upon test

Manual Digital Rockwell Hardness Tester

Humidity : 80%

Number of Specimens : Single specimen

Accuracy : 1%

Test Speed : Standard

Control Mode : Manual and Digital

Response Time : Instantaneous

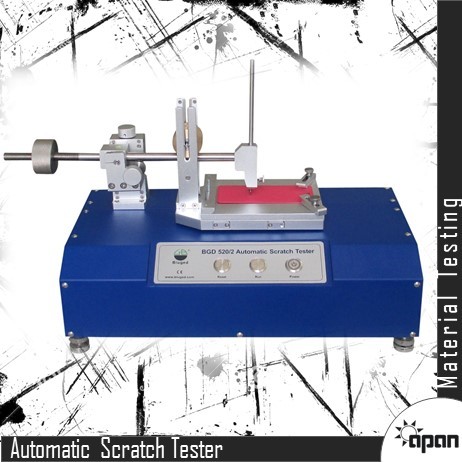

Automatic Scratch Tester

Humidity : 3080% RH

Number of Specimens : 1

Accuracy : 1%

Test Speed : 10200 mm/min (adjustable)

Control Mode : Automatic & Manual

Response Time : <1 sec

Portable Hardness Tester

Humidity : 90% RH

Number of Specimens : 1 at a time

Accuracy : 4 HL (0.5% at 800 HL)

Test Speed : Standard, per ASTM E110

Control Mode : Manual

Response Time : <2 seconds

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry