Pencil Hardness Tester

Price 1 INR/ Kit

Pencil Hardness Tester Specification

- Application

- Wolff Wilborn Pencil Test

- Usage

- Pencil Scratch Method.

- Specimen Size

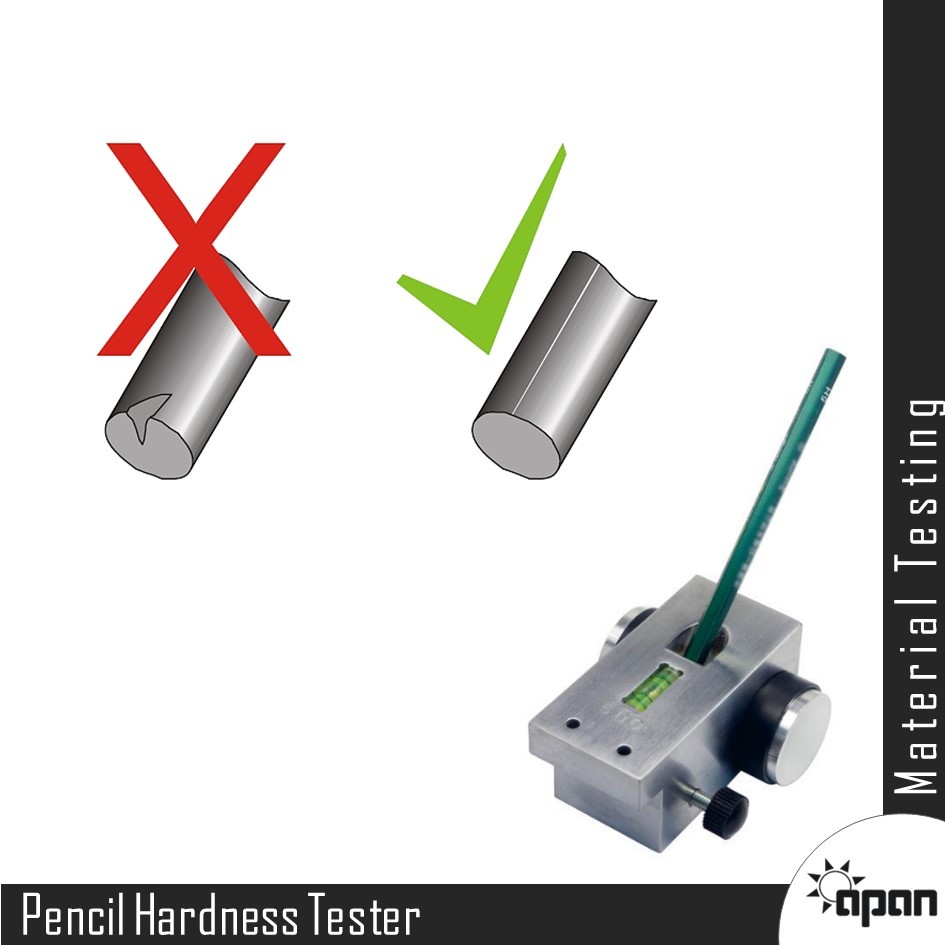

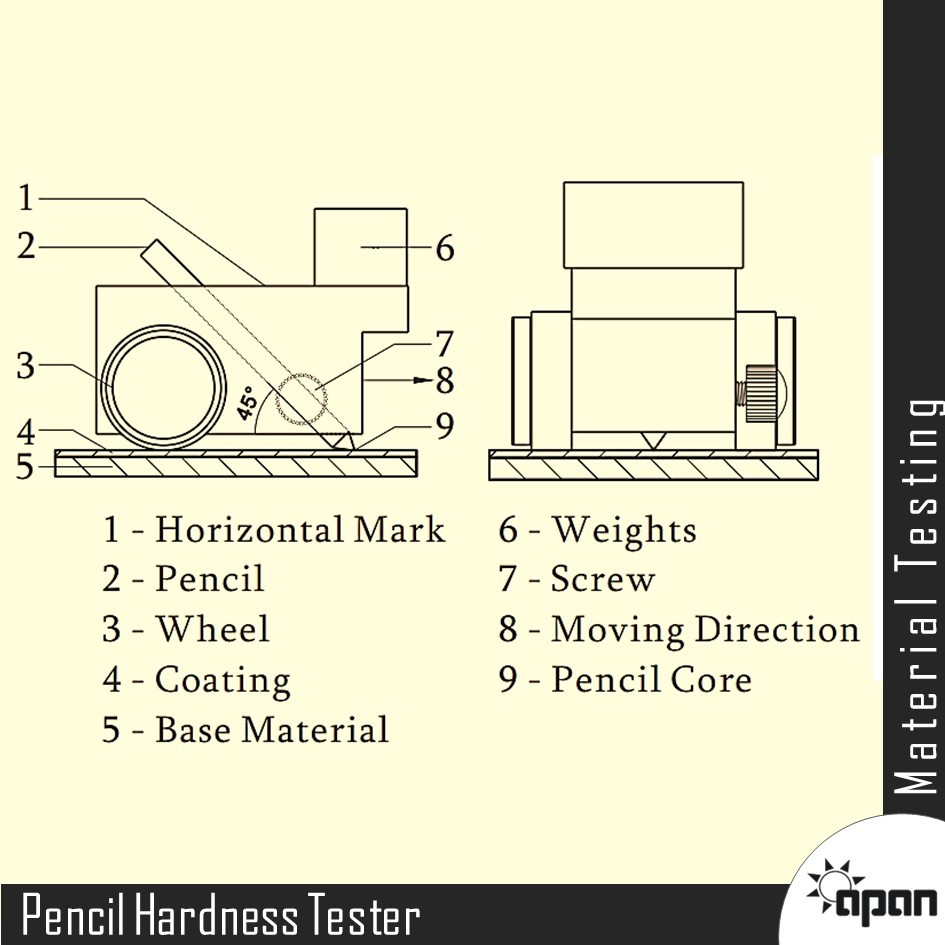

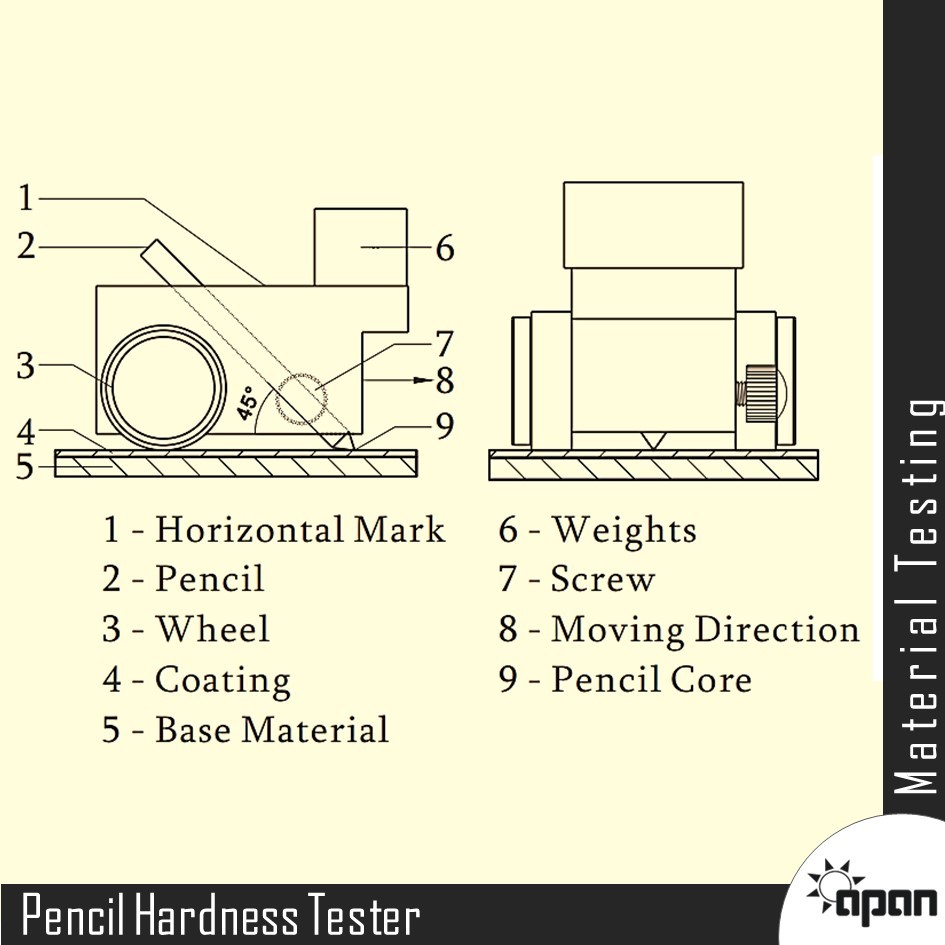

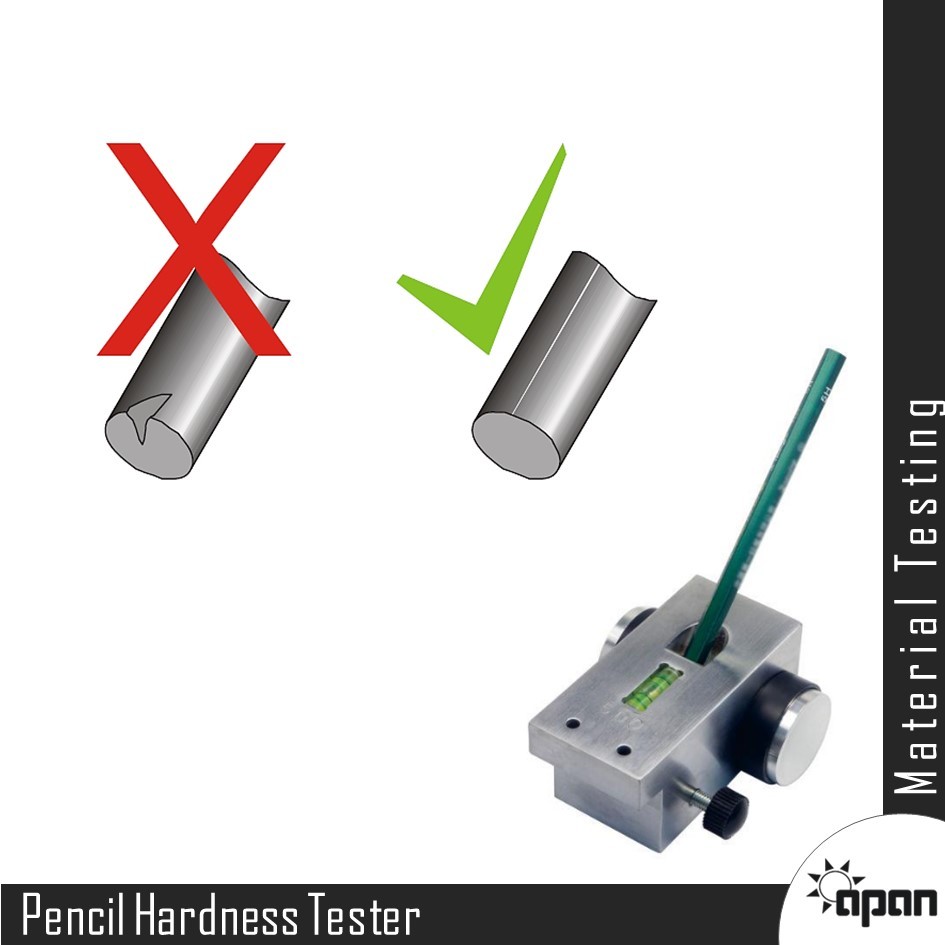

- Two Wheels,a Pencil Core Millimeter (mm)

- Operate Method

- Manual

- Machine Weight

- 1000g / 750g / 500g Kilograms (kg)

- Test Speed

- Measurement Angle 45

- Control Mode

- Manual

Pencil Hardness Tester Trade Information

- Minimum Order Quantity

- 1 Kit

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Kit Per Day

- Delivery Time

- 1 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Pencil Hardness Tester, 1000g Weight, 750g Weight, 13 Pencils6B-6H, Eraser, Knife, Horizontal Pad Block, Sandpaper.

- Certifications

- ASTM D 3363, BS 3900-E19, ECCA T4, EN 13523-4, ISO 15184, JIS K 5600-5-4

About Pencil Hardness Tester

FAQs

What is Pencil Hardness ?

Hardness, in the coated film industry, is the capacity of a given coated surface to resist scratching, marring or gouging. When expressing the measurement of pencil hardness, we do so with a value scale that ranges from 6B, softest, to 9H, hardest (See image 1-1 for the full scale). Typically, films such as polyester and polycarbonate fall in the ranges of B to 4H depending on if the film is uncoated or coated, and if it is coated, what properties the coating offers. The value is recorded as the hardest pencil that does not scratch or mar the surface of the coating.

How do you Measure Pencil Hardness?

Standardized Procedure.

What is the purpose of pencil hardness test?

A pencil hardness test is a kind of assessment technique that is performed to decide the hardness of a material, ordinarily covering materials. To play out a pencil hardness test, graphite pencils of differing hardness are gotten across a coverings surface.

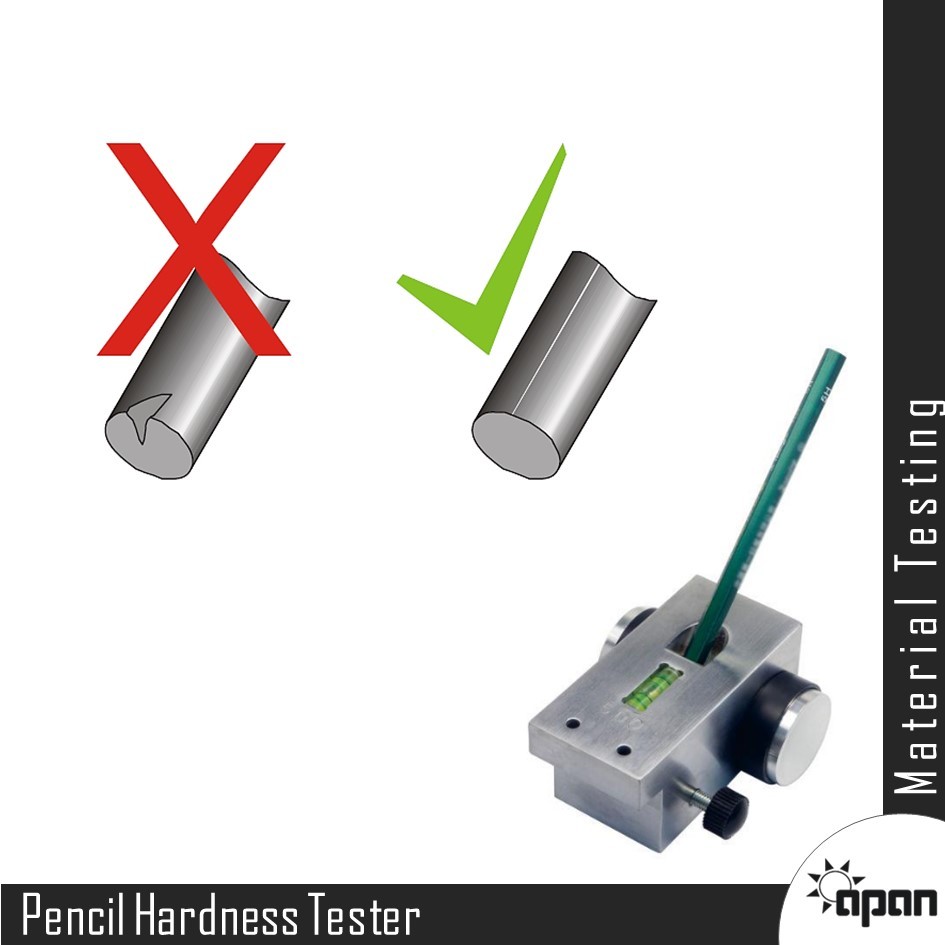

What precautions should be taken when performing a hardness test?

Accurate hardness values may not be obtained if foreign matter such as dust, rust, or oil is included on contact surfaces.

Precision in Surface Testing

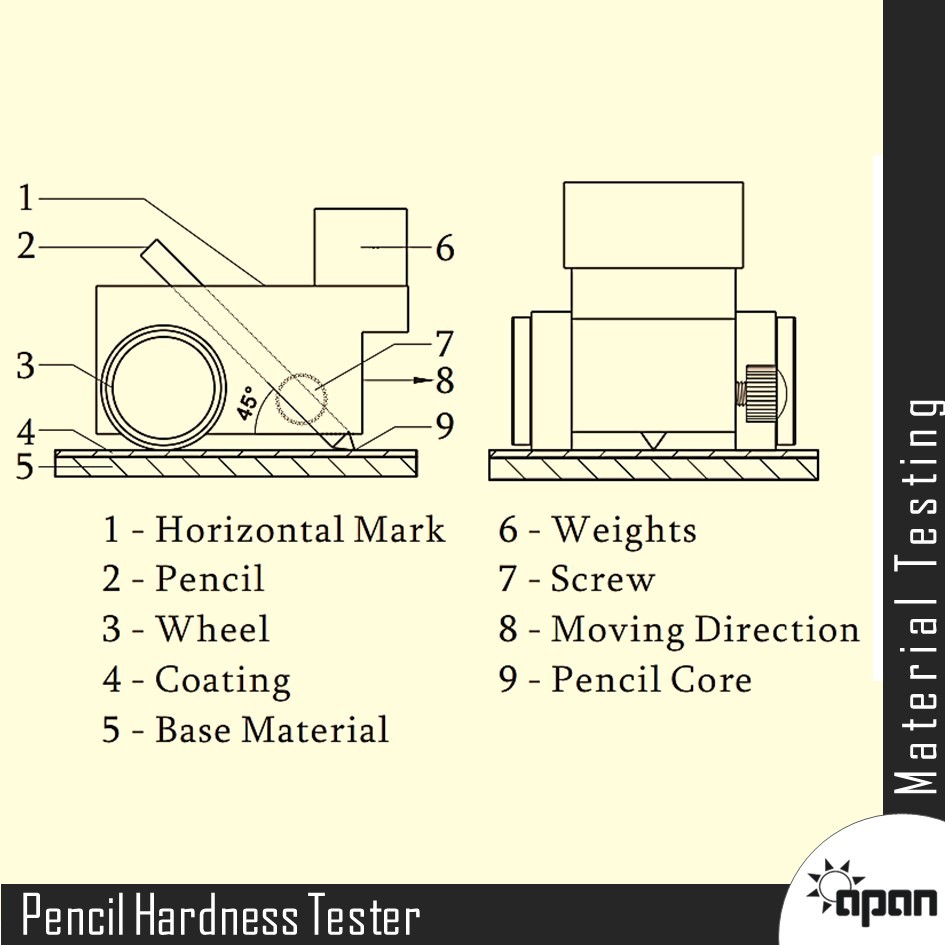

Utilizing the accepted Wolff Wilborn Pencil Method, this tester brings laboratory-level accuracy to your quality control processes. The 45 measurement angle ensures repeatable and reliable results, making it an indispensable choice for manufacturers and testers concerned with coatings and protective layers.

Flexible and User-Friendly Operation

Engineered for manual use, the Pencil Hardness Tester accommodates a variety of pencil core sizes and specimen dimensions with its two-wheel configuration. The robust manual control offers intuitive operation, giving users precision control over the entire testing process.

FAQs of Pencil Hardness Tester:

Q: How does the Pencil Hardness Tester operate during the Wolff Wilborn Pencil Test?

A: The tester is used by inserting a pencil of specified hardness into the holder and applying it at a 45 angle onto the test surface. Manually moved using the two-wheel system, it determines the resistance of the coating to scratching, allowing you to gauge hardness effectively.Q: What is the recommended usage process for this tester?

A: Begin by selecting the appropriate pencil core size, insert it into the tester, and align it at a 45 angle on the specimen. Move the tester manually across the surface to observe if it scratches. Progress through pencils of increasing hardness until the coating is marked, noting the hardness level at which this occurs.Q: When should this Pencil Hardness Tester be employed?

A: This device should be used whenever evaluating the scratch resistance or durability of coatings, lacquers, or painted surfaces is requiredcommonly during production, quality control, or R&D processes.Q: Where can this tester be sourced in India?

A: This product is available through verified distributors, exporters, importers, suppliers, traders, and wholesalers across India, making it accessible to a wide range of industrial sectors.Q: What are the advantages of using a manual control mode for testing?

A: Manual control provides users with superior adaptability and precision during the test. It allows operators to adjust speed and pressure based on specific specimen requirements, resulting in more reliable and tailored outcomes.Q: What specimen sizes and pencil core diameters does this tester accommodate?

A: The tester is designed for use with two-wheel specimen sizes and supports various pencil core diameters in millimeters, providing flexibility for diverse testing applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Manual Digital Rockwell Hardness Tester

Features : High precision, easy operation, digital readout

Automation Grade : Manual

Test Stroke : 50 mm

Power Supply : 220 V / 50 Hz

Mounting Type : Bench top

Measuring Range : 20~100 HRC (Rockwell C)

Digital Rockwell & Superficial Hardness Tester

Features : Digital Display, Automatic Loading/Unloading, Memory Function

Automation Grade : SemiAutomatic

Test Stroke : Vertical, 150 mm

Power Supply : 220V AC, 50Hz

Mounting Type : Bench / Table Top

Measuring Range : HRB, HRC, HR15N, HR15T, HR30T, HR45T, HR15W, HR30W, HR45W

Digital RockwellHardness Tester

Features : Direct digital reading, memory function, automatic/manual operation modes

Automation Grade : Semiautomatic

Test Stroke : 15 mm

Power Supply : 220V AC, 50 Hz

Mounting Type : Benchtop

Measuring Range : 20100 HRC

Digital Magnetic Rockwell Hardness Tester

Features : Magnetic base, touchscreen, automatic loading/unloading

Automation Grade : Semiautomatic

Test Stroke : 50 mm

Power Supply : AC 220V, 50Hz

Mounting Type : Benchtop

Measuring Range : 20~100 HRC

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry