Precision Thickness Gauge

Precision Thickness Gauge Specification

- Test Range

- 0-10 mm

- Temperature

- 5C~40C (Operating)

- Accuracy

- 0.01 mm

- Hardness

- Hardened Steel Contact Point

- Power Supply

- No Power Required

- Application

- Thickness measurement of films, sheets, foils, paper and other materials

- Equipment Type

- Precision Thickness Gauge

- Number of Specimens

- 1

- Automation Grade

- Manual

- Response Time

- Instantaneous

- Display Type

- Dial/Analog

- Mounting Type

- Bench Top

- Resolution

- 0.001 mm

- Measuring Range

- 0-10 mm

- Specimen Size

- Up to 60 mm width

- Features

- Corrosion resistant body, Portable, Lightweight, Easy to use

- Max Height

- Approx. 150 mm

- Humidity

- 0-80% RH (Operating)

- Usage

- Laboratory and Industrial

- Capacity

- Thickness Measurement

- Machine Weight

- Approx. 5 kg

- Test Speed

- Manual

- Test Width

- 60 mm

- Test Stroke

- 0-5 mm

- Control Mode

- Dial/Analog

- Compliance

- IS: 7016/ASTM D374

- Contact Point Diameter

- 6 mm

- Finish

- Powder Coated/Polished

- Material

- Stainless Steel/Aluminium

About Precision Thickness Gauge

As an Authorized dealer we are engaged in providing the broad assortment of "NDT Instrument" for various applications.

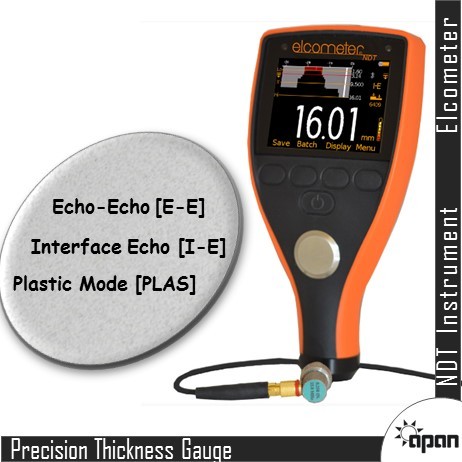

The PTG8 is the top of the range gauge with all the features and functionality necessary for measuring, with precision, material thickness on virtually any material.

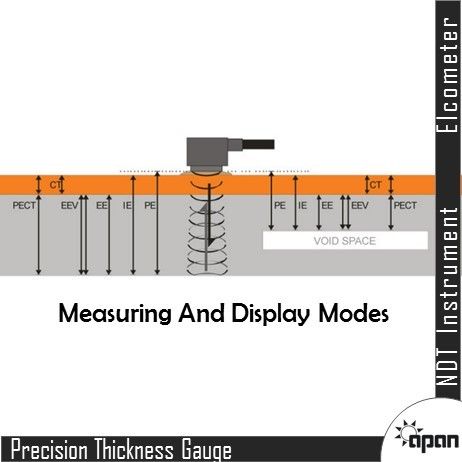

- Interface Echo (I-E) Echo-Echo (E-E) ) & Plastic Mode (PLAS) measurement modes

- Measurement range from 0.15mm (0.006") to 25.40mm (1.00")

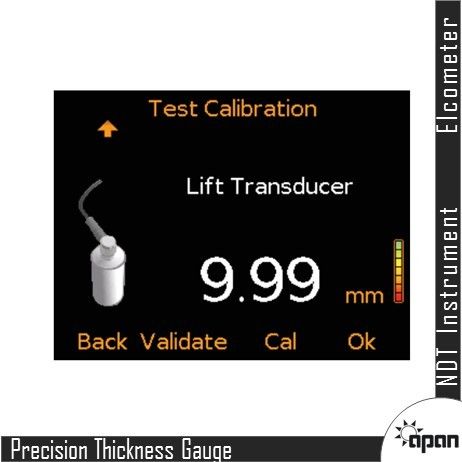

- 2-Point, 1-Point, Material & Factory Calibration options

- Three user programmable calibration memories

- User selectable measurement rate; 4,8,16 readings per second

- User selectable reading resolution; 0.1mm (0.01") or 0.01mm (0.001")

- Scan Mode

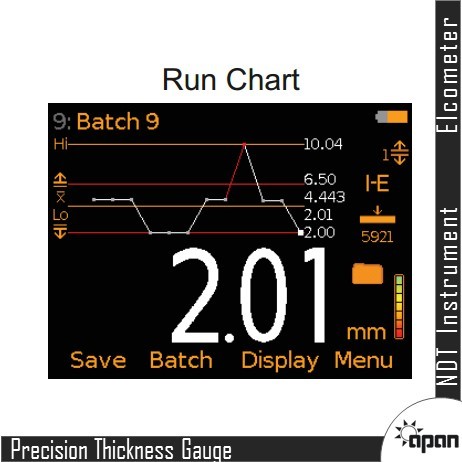

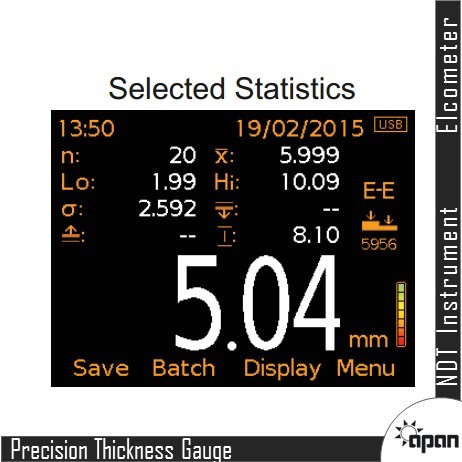

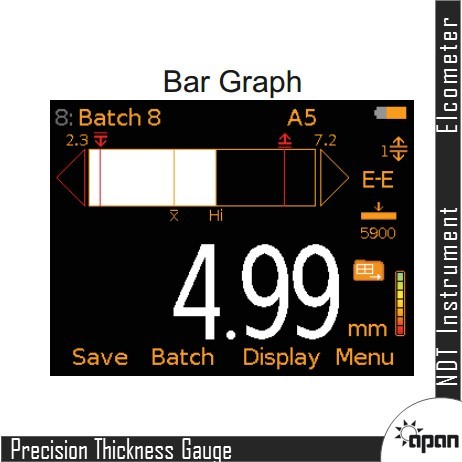

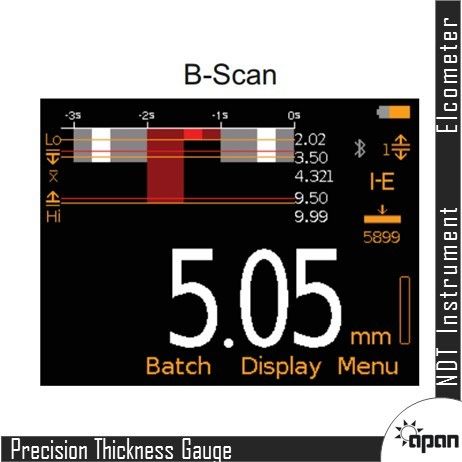

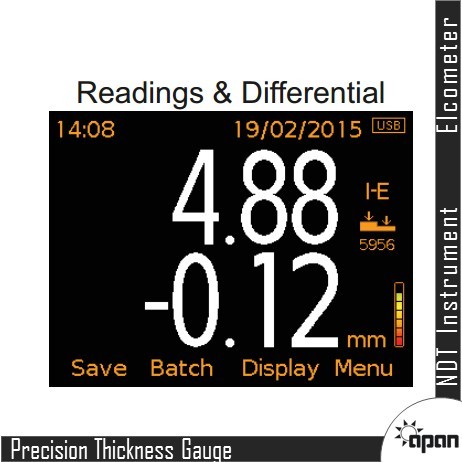

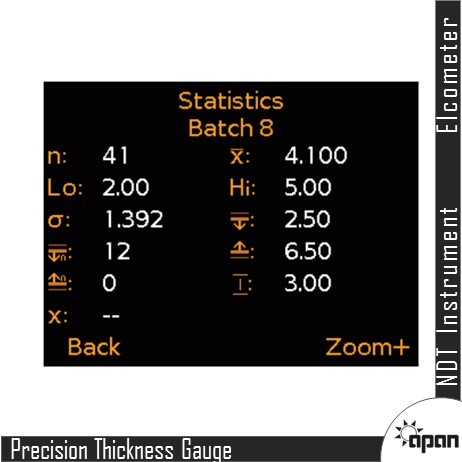

- Readings, selected statistics, Bar Graph, Run Chart, B-Scan & Differential Mode

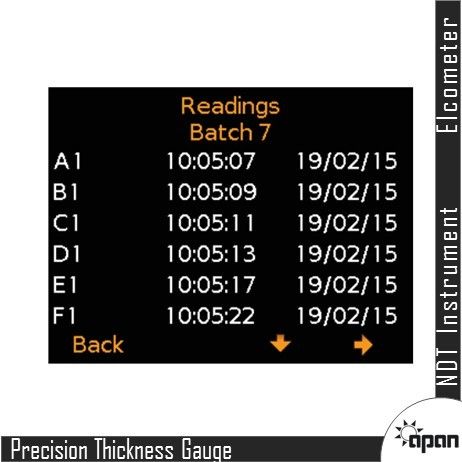

- Gauge memory; stores upto 100,000 readings in up to 1,000 sequential or grid batches

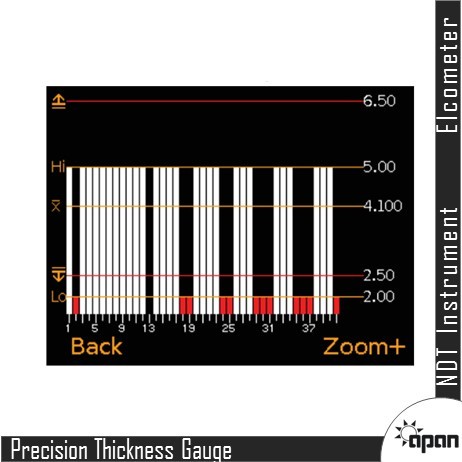

- User definable upper and lower limits with audible & visual pass/fail warnings

- USB and Bluetooth data output to ElcoMaster and ElcoMaster Mobile Apps

All gauges have a fully customisable, scratch and solvent resistant colour LCD display. Measurement modes available include Pulsed-Echo (P-E), Echo-Echo ThruPaint (E-E), Interface Echo (I-E), Plastic Mode (PLAS) and Velocity mode (VM) (for more information on measurement modes, see page 3). A choice of measurement units are available, depending on the measurement mode selected. A stability indicator shows clearly both the strength and reliability of the ultrasonic signal.

When enabled, users can slide the transducer over a large surface area whilst the gauge takes readings at a rate of 16 Hz (16 readings per second). During each scan, the live thickness is displayed together with an analogue bar graph showing the thickness relative to the set nominal value and any user defined limits, with audible and visual warnings if any readings fall outside the set limits. When the transducer is lifted off the surface, the average, lowest and highest thickness value is displayed making scan mode ideal for checking a samples overall uniformity.

A trend graph of the last 20 readings, showing the variation in material thickness over the test area. The graph is updated automatically as each reading is taken and any readings outside the set and enabled limits are displayed in red thus allowing the user to easily identify areas where corrosion may be present or the material is too thick for purpose.

Velocity mode measures the speed of sound of materials and is ideal for determining the homogeneity of a material/alloy and the correct velocity of a material for calibration.

A time based, cross sectional 2 dimensional B-Scan provides a graphical view of the material under test, ideal for relative depth analysis. The zoom of the B-Scan reading can either be set to automatic or can be defined by the user to focus on areas of interest.

Plastic mode is specifically designed for measuring very thin plastics.

Robust Construction for Lasting Performance

Crafted with stainless steel and aluminium, the gauge boasts a powder-coated or polished finish for corrosion resistance. Its precision contact point is made of hardened steel, offering reliable measurements and enhanced durability. The bench-top mounting and lightweight design make it easy to transport and ideal for demanding industrial or laboratory environments.

Manual Control for Immediate and Accurate Readings

Operation is manual, eliminating the need for a power supply. With an analog dial display, users receive instant readings, facilitating timely quality checks. The gauges control mode and straightforward usage ensure repeatable results in a wide range of operating conditions, from humidity up to 80% RH and temperatures from 5C to 40C.

FAQs of Precision Thickness Gauge:

Q: How do I operate the Precision Thickness Gauge for measuring sample thickness?

A: To measure thickness, place your specimen (up to 60 mm width) beneath the hardened steel contact point, adjust the dial using manual control, and read the measured value directly from the analog display. The process is straightforward, requiring no power supply or special setup.Q: What types of materials can this thickness gauge measure?

A: This gauge is suitable for films, sheets, foils, paper, and other similar materials. Its measuring range of 0-10 mm and specimen width capacity up to 60 mm accommodate a wide variety of sample types in both laboratory and industrial settings.Q: When is it necessary to use a manual precision thickness gauge over an automated device?

A: Manual gauges like this are preferred when portability, instantaneous readings, and independence from external power sources are crucial. Theyre ideal for quick spot checks, environments lacking electricity, or situations requiring a lightweight and bench-top mounted device.Q: Where can I use the Precision Thickness Gauge effectively?

A: This gauge is designed for laboratory and industrial environments. It can be used wherever accurate thickness measurements of materials are needed, including manufacturing facilities, quality control labs, and research settings in India and internationally.Q: What benefits does the hardened steel contact point provide during testing?

A: The hardened steel contact point offers superior wear resistance, ensuring accurate measurements over time. It maintains consistency when checking various specimens and supports reliable results in demanding applications.Q: How is the gauge maintained for optimal performance?

A: Regular cleaning of the contact point and dial surface, as well as storing the gauge in a dry environment, will maintain its accuracy and prolong its lifespan. Thanks to its corrosion-resistant body, minimal maintenance is required beyond basic care.Q: What compliance standards does the gauge meet, and how does this affect usage?

A: The Precision Thickness Gauge complies with IS: 7016 and ASTM D374 standards, ensuring its measurements align with industry benchmarks for film, sheet, and foil testing. This makes the gauge suitable for laboratory certification and quality assurance purposes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in NDT Equipment Category

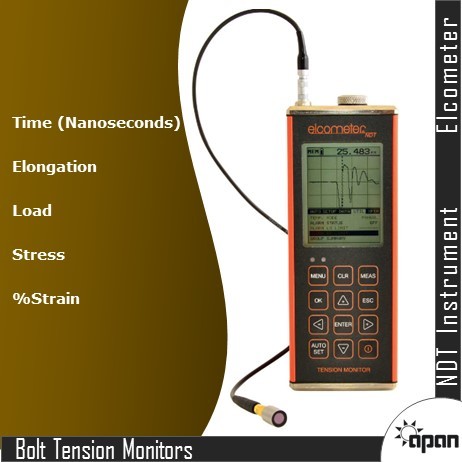

Bolt Tension Monitors

Automation Grade : Automatic

Application : Measuring bolt tension during tightening

Power Supply : 220 V AC, 50 Hz

Accuracy : 1% F.S.

Temperature : 0C to 50C

Test Range : 0100 kN

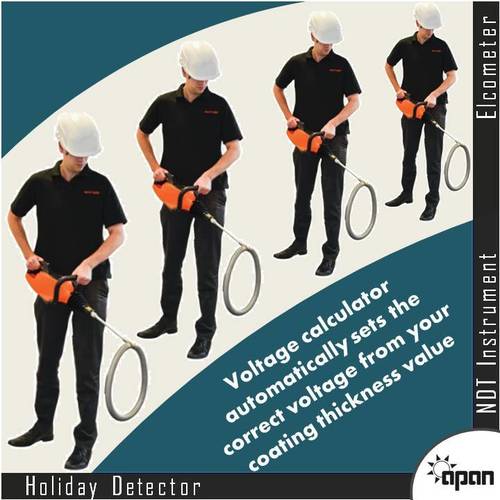

Elcometer 280 Pulsed DC Holiday Detector

Automation Grade : Manual

Application : Detects holidays (pinholes, porosity, flaws) in coatings on conductive substrates

Power Supply : Rechargeable Liion battery pack, 12V DC, 4400mAh

Accuracy : (5% + 5 digits)

Temperature : Operating: 10C to +50C (+14F to +122F)

Test Range : DC Pulsed voltage 0.5kV30kV

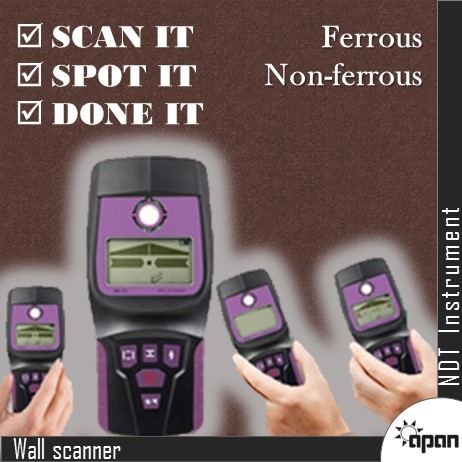

Wall Scanner

Automation Grade : Manual

Application : Detection of metal, wood, AC wires behind wall surfaces

Power Supply : 9V battery

Accuracy : 1 mm (approx.)

Temperature : 10C to 50C

Test Range : Up to 100 mm (for metal); up to 38 mm (for wood)

Needle Pressure Gauge

Automation Grade : Manual

Application : Industrial, Laboratory, Hydraulic and Pneumatic Systems

Power Supply : Not Required (Mechanical Gauge)

Accuracy : +/2% F.S.

Temperature : 20C to 60C

Test Range : 0~3000 psi

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry