Rotational Viscometer

Rotational Viscometer Specification

- Humidity

- 80% RH

- Power Supply

- 220V 10%, 50Hz

- Measuring Range

- 12,000,000 mPas

- Operating Voltage

- 220V

- Port Size

- Standard spindle interface

- Specimen Size

- 2030 ml typical sample volume

- Frequency

- 50 Hz

- Interface Type

- RS232/USB

- Test Range

- 12,000,000 mPas

- Features

- Auto-Range, Overload Protection, Real-time Data Display

- Display Type

- Large Digital LCD Display

- Accuracy

- 1.0% of full scale

- Temperature

- 5C35C (operating range)

- Number of Specimens

- 1 per test cycle

- Response Time

- 6 seconds

- Equipment Type

- Rotational Viscometer

- Automation Grade

- Semi-Automatic

- Max Height

- 42 cm (assembled)

- Application

- Viscosity measurement of liquids and semi-solids in laboratories, research, quality control

- Mounting Type

- Bench-top

- Resolution

- 0.01 mPas

- Usage

- Laboratory, industrial, quality assurance

- Machine Weight

- 6.8 kg

- Test Speed

- 0.1200 rpm

- Control Mode

- Digital Control with Touchscreen

Rotational Viscometer Trade Information

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

About Rotational Viscometer

Our clients widely reckon us as the topmost and reputed supplier of an excellent quality Rotational Viscometer. This instrument is used for measuring the viscosity of various paints and coatings. Offered to clients in a wide range of specifications and models so that their requirements can be fulfilled, this Rotational Viscometer is stringently inspected based on standard quality parameters.

Features:

- Easy to use

- Supreme finishing

- High end performance

Specification

- 19 speeds from 0.3 rpm to 200 rpm

- PT100 temperature probe

- RS 232 interface

Precision and Versatility for Viscosity Testing

With four standard spindles and test speeds ranging from 0.1 to 200 rpm, this rotational viscometer accommodates a wide variety of samplesideal for laboratory, quality assurance, and R&D workflows. Its broad measuring range and automatic calibration guarantee consistency and reproducibility, even with diverse specimen types such as water-based and oil-based liquids or semi-solids.

User-Friendly Features and Durable Design

Designed for seamless operation, the viscometer is equipped with a large LCD touchscreen, intuitive digital controls, and multi-language support. The inclusion of a sturdy ABS transport case makes it suitable for both stationary and transportable testing environments. Overload protection and auto-range functionality add further reliability, while operating noise remains minimal (<60 dB).

Data Management and Connectivity

Securely store up to 30 test results for future analysis or quality recordkeeping. With RS232 and USB interface options, data transfer is simplified, supporting integration with laboratory information systems. Rapid response and real-time data visualization facilitate prompt workflow decisions and accurate reporting in industrial and research settings.

FAQs of Rotational Viscometer:

Q: How does the rotational viscometer perform automatic calibration?

A: The viscometer uses a motor-driven automatic calibration process, which adjusts the instruments measurement system at the push of a button, ensuring accurate results without requiring manual adjustments or external calibration weights.Q: What types of materials can be tested with this viscometer?

A: This instrument is compatible with both water-based and oil-based samples, making it suitable for a broad range of liquids and semi-solids in laboratory, industrial, and quality control applications.Q: When should I use each of the included standard spindles (L1L4)?

A: The four standard spindles are designed for different viscosity ranges. Select the appropriate spindle based on your samples expected viscosity using the guidelines provided in the product manuallower number spindles for low-viscosity samples, and higher number spindles for thicker materials.Q: Where can data be exported and how is data stored?

A: Up to 30 test results are stored internally on the viscometer. You can export this data via the built-in RS232 or USB interface for use with external computers or laboratory information management systems.Q: What is the typical sample volume required for a viscosity test?

A: A single test cycle requires approximately 20-30 ml of your liquid or semi-solid sample, optimizing material usage while ensuring measurement accuracy.Q: How does the touchscreen digital control panel benefit users?

A: The touchscreen control panel streamlines set-up, method selection, data monitoring, and review, while the multi-language interface allows operators from different regions to use the equipment comfortably and efficiently.Q: What are the environmental requirements for reliable operation?

A: The viscometer should be used in conditions with an ambient temperature between 5C and 35C and humidity no greater than 80% RH, ensuring optimal performance and measurement consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Analytical Lab and Field Category

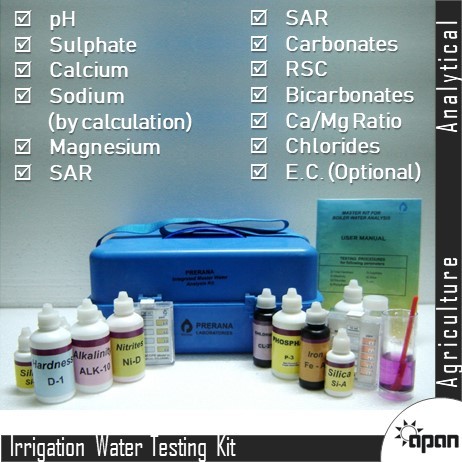

Irrigation Water Testing Kit

Accuracy : 0.1 for pH; 2% FSD for EC

Temperature : 545C Operating range

Features : Field portable, easytouse, premeasured reagents, quick visual results, includes all accessories

Machine Weight : Lightweight; approx. 1.5 kg (with carry case)

Response Time : Less than 5 min/parameter

Number of Specimens : Multiple water samples per session

Ozone Testing Kit

Accuracy : 0.05 ppm

Temperature : Room Temperature (10C 40C)

Features : Portable, easy to use, ready to use reagents, safe packaging

Machine Weight : 1.5 kg

Response Time : Within 2 minutes

Number of Specimens : Multiple: can test up to 10 samples at once

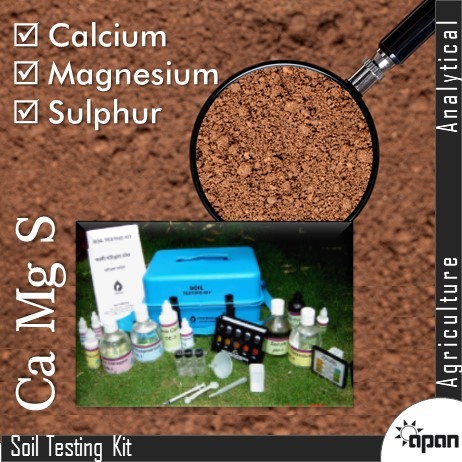

Soil Testing Kit - Secondary

Accuracy : Based on color chart and visual comparison

Temperature : 10C to 40C (operational)

Features : Portable, easy to use, field applicable, no electricity required

Machine Weight : 2.7 kg

Response Time : 510 minutes per test

Number of Specimens : Can test 50 samples per kit (approx)

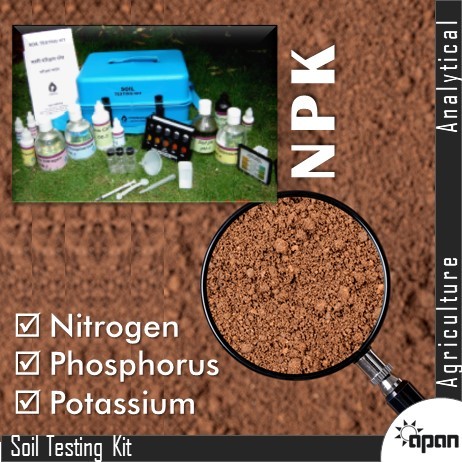

Soil Testing Kit - Primary

Accuracy : +/ 5%

Temperature : 0C to 50C (operating)

Features : Portable, easytouse, no power required

Machine Weight : Approx 600 gm

Response Time : < 10 minutes

Number of Specimens : Up to 10 tests per kit

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry