Digital Magnetic Rockwell Hardness Tester

Digital Magnetic Rockwell Hardness Tester Specification

- Application

- Rockwell hardness testing on ferrous and non-ferrous metals

- Frequency

- 50Hz

- Resolution

- 0.1 HRC

- Specimen Size

- Max. 200 mm height

- Hardness

- Rockwell (HRC, HRB, etc.)

- Response Time

- <3 seconds

- Equipment Type

- Digital Magnetic Rockwell Hardness Tester

- Port Size

- Standard 16 mm test port

- Humidity

- 80% RH

- Mounting Type

- Bench-top

- Power Supply

- AC 220V, 50Hz

- Features

- Magnetic base, touch-screen, automatic loading/unloading

- Display Type

- Large digital LCD

- Max Height

- 200 mm

- Operating Voltage

- 220V AC

- Interface Type

- USB and RS232

- Accuracy

- 1 HRC

- Test Range

- 20~100 HRC

- Measuring Range

- 20~100 HRC

- Temperature

- 10C ~ 40C

- Automation Grade

- Semi-automatic

- Number of Specimens

- 1 at a time

- Usage

- Industrial metal hardness testing

- Test Speed

- Adjustable, up to 2 mm/s

- Test Stroke

- 50 mm

- Control Mode

- Digital touch control

Digital Magnetic Rockwell Hardness Tester Trade Information

- Main Export Market(s)

- Asia

About Digital Magnetic Rockwell Hardness Tester

We feel immense pleasure in introducing our company as the foremost supplier of Digital Magnetic Rockwell Hardness Tester. Offered to clients in different specifications and models so that their requirements can be fulfilled, it is procured from reputed vendor in market. This equipment is used for testing the hardness of different types of metals and alloys. We make sure to check the functioning and durability of the Digital Magnetic Rockwell Hardness Tester prior to final delivery in market.

Features:

- Digital screen

- Accuracy in result

- Rugged design

Advanced Touch-Screen Control

Operating the Digital Magnetic Rockwell Hardness Tester is intuitive and streamlined, thanks to its large digital LCD and responsive touch-panel interface. Users benefit from quick settings adjustments, data input, and process monitoring, making the instrument highly suitable for precision-driven industrial testing environments.

Magnetic Base and Precision Testing

The powerful magnetic base, delivering force exceeding 600 N, ensures stable placement and reliable measurement on various metal surfaces. Its adaptability to a wide range of specimen dimensions, including a maximum height of 200 mm and thickness as low as 1 mm, accommodates versatile industrial applications.

Efficient Data Management and Calibration

With onboard storage capacity for 20,000 results and seamless Windows-based software integration, the tester simplifies data storage, review, and export. The built-in auto-calibration feature guarantees consistent accuracy, reducing time needed for manual calibration and ensuring trustworthy measurement results every time.

FAQs of Digital Magnetic Rockwell Hardness Tester:

Q: How does the Digital Magnetic Rockwell Hardness Tester improve testing efficiency in industrial environments?

A: This hardness tester offers automated loading/unloading, swift response time (<3 seconds), and large onboard data storage, allowing users to complete more tests quickly and manage results efficiently. The magnetic base ensures stability during measurements, making the tester highly effective for high-throughput industrial settings.Q: What types of samples and metals can this tester handle?

A: Designed for Rockwell hardness testing on ferrous and non-ferrous metals, the tester accommodates specimens up to 200 mm in height and at least 1 mm in thickness. It is suitable for various industrial metal components requiring hardness quality checks within the 20~100 HRC measuring range.Q: When is calibration required, and how is it performed?

A: Calibration is automatically managed by the built-in auto-calibration system. It is suggested to regularly verify calibrationespecially after long periods of use or significant test volumeto maintain consistent accuracy (1 HRC), but the automated process eliminates the need for manual recalibration.Q: Where can this hardness tester be installed and used?

A: The tester is designed for bench-top mounting and operates efficiently in industrial laboratories or quality control departments, particularly in manufacturing, metallurgy, or metalworking industries across India. Its robust design and operating temperature range (10C to 40C) accommodate diverse environments.Q: What process is involved in performing a Rockwell hardness test with this equipment?

A: Begin by positioning the metallic specimen under the indenter. The digital touch-screen interface allows you to set parameters such as test load and speed (up to 2 mm/s). Initiate the test, and the automated system will load, measure, and unload, displaying results on the LCD within three seconds.Q: How is test data stored and managed?

A: Test results are automatically saved in the devices memory, with a capacity for storing up to 20,000 individual measurements. Users can export data to a computer using USB or RS232 connectivity and manage it via Windows-based software for detailed analysis and record-keeping.Q: What are the primary benefits of using this Rockwell Hardness Tester?

A: Key benefits include precise hardness measurements with high accuracy and resolution, user-friendly digital controls, large test data capacity, automatic calibration, adaptability for different specimen sizes, and seamless integration with computer systems. This ensures reliability and efficiency in metal hardness quality assurance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

Automatic Digital Rockwell Hardness Tester

Accuracy : 1 HR

Display Type : Digital LCD

Usage : Laboratory/industrial material hardness measurement

Number of Specimens : Multiple consecutive tests possible

Temperature : 10C ~ 35C

Automation Grade : Automatic

Portable Hardness Tester

Accuracy : 4 HL (0.5% at 800 HL)

Display Type : LCD digital display

Usage : Metal hardness testing

Number of Specimens : 1 at a time

Temperature : 0C to 50C

Automation Grade : Manual

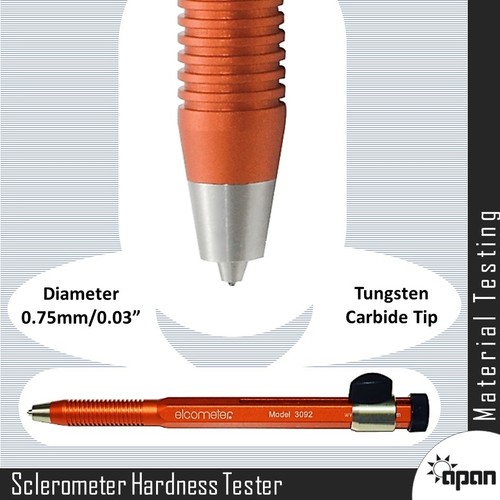

Sclerometer Hardness Tester

Accuracy : 1 HV

Display Type : Analog

Usage : Surface Hardness Testing

Number of Specimens : 1

Temperature : 5C 40C

Automation Grade : Manual

Leeb Hardness Tester

Accuracy : 6 HL (0.5% at 800 HL)

Display Type : LCD digital display

Usage : Nondestructive hardness testing of metals

Number of Specimens : Single or multiple, depending on application

Temperature : 0C to 40C

Automation Grade : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry