Rebound Hammer

Rebound Hammer Specification

- Display Type

- Analog Scale

- Specimen Size

- Minimum cube size 150 mm 150 mm 150 mm

- Resolution

- 1 N/mm

- Measuring Range

- 10 70 MPa

- Hardness

- Measures concrete surface hardness

- Equipment Type

- Rebound Hammer

- Mounting Type

- Handheld

- Accuracy

- 1 N/mm

- Humidity

- 90% RH

- Temperature

- 0C 40C

- Application

- Concrete Surface Hardness Testing

- Power Supply

- Not Required (Manual Operated)

- Number of Specimens

- Single Specimen

- Features

- Portable, Lightweight, Corrosion-resistant body

- Response Time

- Instantaneous

- Automation Grade

- Manual

- Test Range

- 10 70 N/mm

- Usage

- Non-destructive concrete strength estimation

- Capacity

- 2.207 Joules impact energy

- Machine Weight

- 1.1 kg

- Control Mode

- Manual

Rebound Hammer Trade Information

- Main Export Market(s)

- Asia

About Rebound Hammer

As a Authorized dealer we are engaged in providing the broad assortment of Elcometer, UK make 'Concrete Inspection' Equipments. Elcometer 181 Analogue Concrete Test Hammer provides a quick, simple and inexpensive method for non-destructive evaluation of concrete compression strength and other masonry materials.

Concrete test hammers are one of the most widely used instruments in the field of non-destructive testing and Elcometer offer both mechanical and digital models.

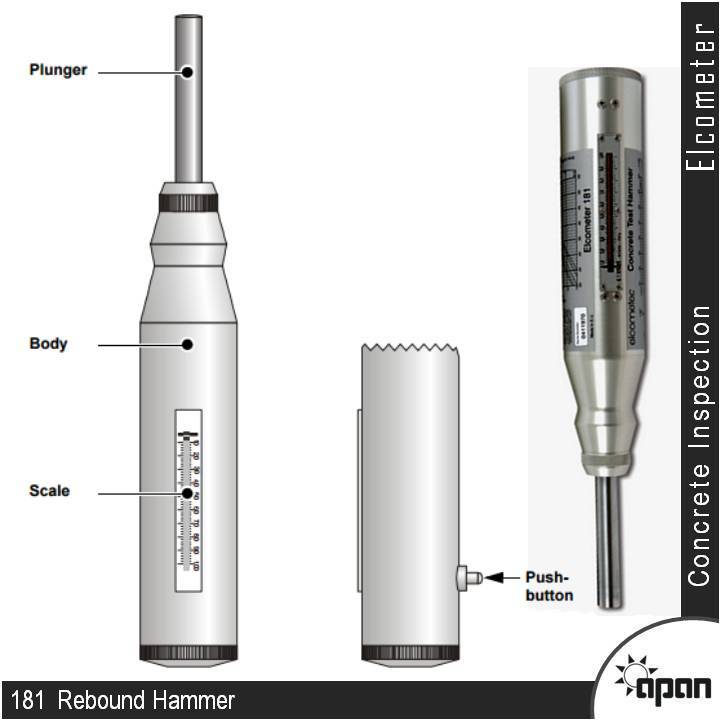

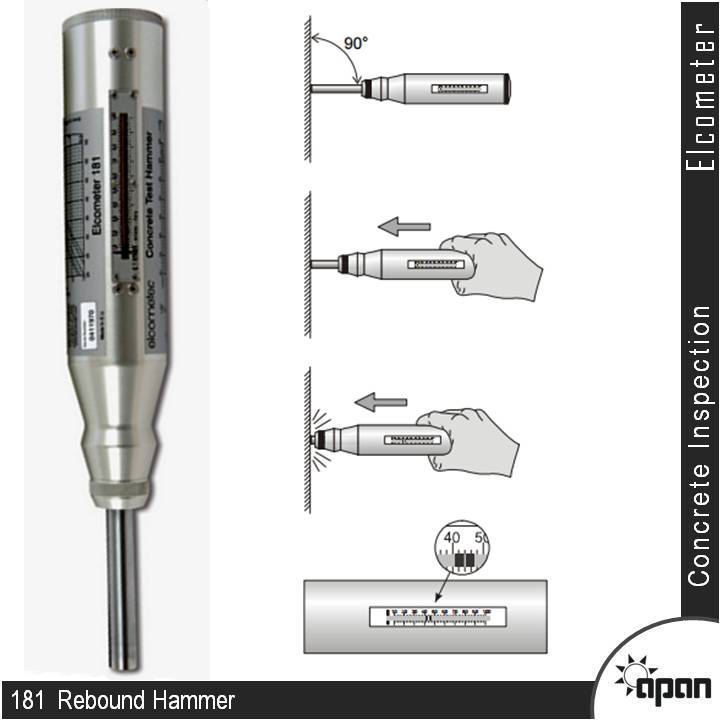

This gauge consists of a spring loaded plunger which, when released, strikes the surface with fixed and constant impact energy. During the rebound stroke, the mass moves a pointer that indicates the maximum point of return and at the same time indicates a reference value called Rebound Number.

This number, converted by the correlations available on the hammer, gives the compression resistance value in respect of the impact angle.

Key Features:

- Impact Energy 2.207 Nm

- Supplied with grinding stone to prepare test surface

- Aluminium body

- Rebound value indicated on test hammer

- Rebound value chart on body, for quick calculation of compressive strength

- Curve selection on chart dependant on testing angle

Accuracy | Better than +/- 2 Rebound Number (When tested on Calibration Anvil at 80) |

Resolution | 2 Rebound Number(s) |

Range | 10 to 100 Rebound Number(s) |

Dimensions | Hammer: 280mm (11.02") length x 55mm (2.17") diameter In Case: 350mm (13.78") length x 80mm (3.15") diameter |

Weight | 1.5kg (3.3lbs) with case |

Packing List | Elcometer 181 analogue concrete test hammer, |

Efficient and Reliable Concrete Testing

Designed specifically for concrete surface hardness assessment, the rebound hammer provides instant readings, facilitating quick decision-making on construction sites. Its robust, corrosion-resistant aluminium body ensures longevity and consistent performance even in demanding environments. With manual control and no requirement for power supply, the tool offers simplicity and reliability during everyday usage.

Certified Accuracy and Standards Compliance

Each rebound hammer is supplied with a calibration certificate, ensuring measurement accuracy within 1 N/mm and adherence to recognized international standards. This ensures that testing results are trusted and suitable for both field application and official reporting. Its analog scale display simplifies the process, making interpretation of results both straightforward and reliable.

Portable Design for On-Site and Laboratory Use

Weighing only 1.1 kg and packed in a convenient carrying case, this hammer is ideal for traders, suppliers, and inspectors who require portability without compromising functionality. The device operates efficiently within 0C to 40C and 90% RH, making it versatile for various testing conditions, with no external power required.

FAQs of Rebound Hammer:

Q: How do you use the Rebound Hammer for concrete surface hardness testing?

A: To use the rebound hammer, hold the device against the prepared concrete surface and press the plunger until it releases. The rebound value can then be read instantly on the analog scale, providing an estimate of concrete strength without causing damage to the specimen.Q: What standards does this Rebound Hammer comply with for quality assurance?

A: The hammer meets IS 13311 (Part 2) 1992, ASTM C805, and EN 12504-2 standards, ensuring its reliability and suitability for professional concrete strength evaluation.Q: When is calibration required for the Rebound Hammer and how is it ensured?

A: Calibration should be performed each time you suspect measurement deviation or after extensive use. The device comes supplied with a calibration certificate, confirming its accuracy at the time of delivery.Q: Where can the Rebound Hammer be used effectively?

A: This portable device is suitable for both field inspections and laboratory environments, operating efficiently across a temperature range of 0C to 40C and humidity up to 90% RH.Q: What is the process for interpreting results using the analog scale?

A: After testing, the rebound value appears on a clear, easy-to-read analog scale. These values correspond directly to concrete compressive strength, allowing quick estimation between 1070 MPa with a resolution and accuracy of 1 N/mm.Q: What are the benefits of using an aluminium alloy body and hardened steel plunger?

A: The aluminium alloy body ensures lightweight portability and resistance to corrosion, while the hardened steel plunger delivers robust, consistent impact for accurate measurements throughout the instruments lifespan.Q: Is the Rebound Hammer suitable for large and small specimen sizes?

A: The instrument requires a minimum specimen cube size of 150 mm 150 mm 150 mm for accurate testing, accommodating most concrete test samples used in construction and quality assessments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Engineering Instrument Category

Rebar Detector

Machine Weight : 1.5 kg

Power Supply : Rechargeable Battery (7.4V, 2200 mAh)

Features : Portable, Lightweight, Audible & Visual Alarm, Data Storage, Backlit Display

Response Time : Instantaneous (<1s)

Automation Grade : SemiAutomatic

Test Range : Rebar diameter 650 mm, depth up to 100 mm

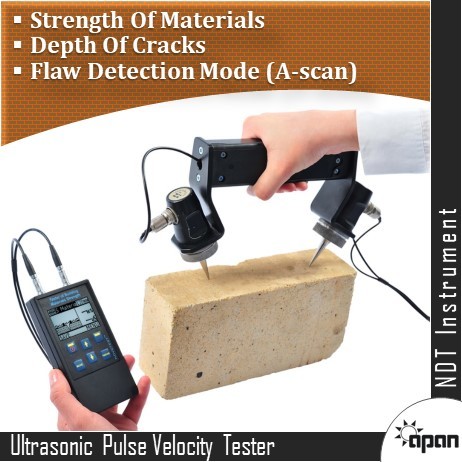

Ultrasonic Pulse Velocity Tester

Machine Weight : Approximately 2.5 kg

Power Supply : Rechargeable battery/AC adapter, 220V 50Hz

Features : Portable, Battery Operated, Data Storage, Backlit Display

Response Time : < 0.5 s

Automation Grade : Semiautomatic

Test Range : 0.1 m to 6 m

Concrete Test Hammer

Machine Weight : About 1 kg

Power Supply : Not required (mechanical operation)

Features : Portable, easy to use, no battery required

Response Time : Instant on impact

Automation Grade : Manual

Test Range : 1070 N/mm (MPa)

Cover meter

Machine Weight : 2.3 kg

Power Supply : Rechargeable Liion battery / 230V AC adapter

Features : Rebar location, cover depth, easy operation, portable

Response Time : Instantaneous

Automation Grade : Manual

Test Range : Up to 180 mm (cover depth)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry