Call:

Showroom

Elcometer we deal in are used to measure the thickness of different non-conducting materials on several conducting surfaces. They are in sync with latest technology and deliver accurate measurement.

Industrial Metrology Tools we deal in are the precision measuring devices, which are used to regulate the parts as well as features. These have tolerance in their functions and work with accuracy.

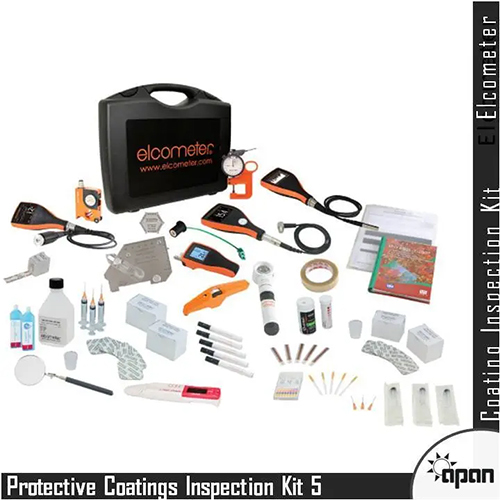

The Coating inspection products we offer are used to can ensure that the vulnerabilities are spotted. Offered products ensure precision and accuracy at highest level. These are used in the failure-analysis services.

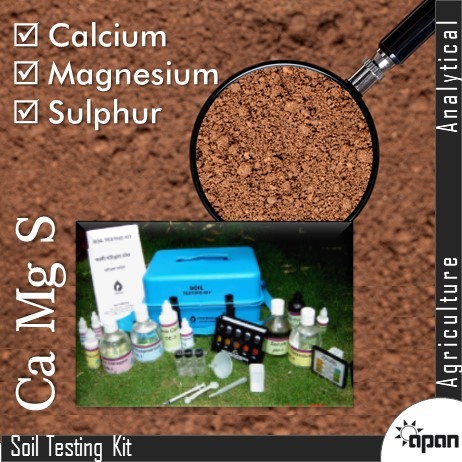

Analytical Lab And Field devices are the easy to use devices, which offer accurate results. These have accessibility in perfect finish and allow for trouble free functionality.

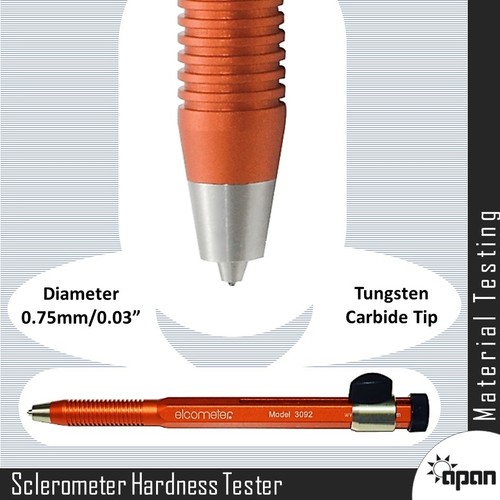

Material testing devices we offer are the equipment that are widely used in the quality control processes. These are suited for the analysis of soils, asphalt, bitumen, concrete, steel, aggregates, cement and mortar.

Civil Engineering Instruments we deal in offer accuracy in results and easy usage. They boast of flawless performance and ensure less power consumption. These are used by the civil engineers for different purposes.

Image Processing Equipment, supplied by us have robust construction, simple operation, longer functional life and easy maintenance. Viewing of image becomes easy and clear with the said solutions.

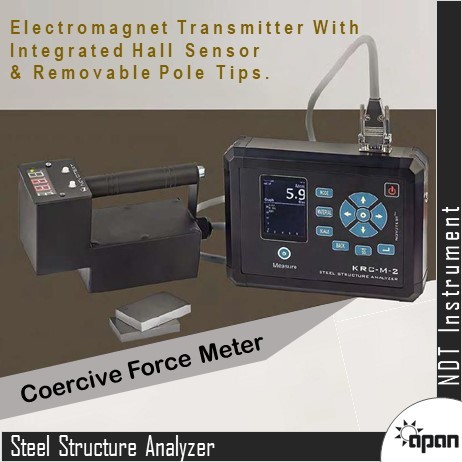

NDT Equipment we deal in are functional as the best-quality inspection instruments. These are suited to determine specific attributes of materials without making damage to the materials that are going through the testing process.

Environmental Monitoring Instruments, we deal in are utilized to assess the quality of natural resources. These also govern the effects of human activity made on the environment. These can measure air, soil quality and water.

Optical Instruments supplied by us are the instruments, which boast of impeccable performance and accurate results. These are made to process the light waves and enhance the image for viewing. Also, these determine as well as analyze the characteristic properties of images.

Visual inspection systems we deal in ensure an increase in uptime as well as improvements in production. Their use can make reduction in the expenses. These contribute to the quality control and ensure functional effectiveness.

Infrared Thermometers are the simple, accurate and comfortable to use modules. These enable simple temperature measurement and allow for boosted precision and quick results. These have the ability to monitor the temperature in several adverse situations.

Testing equipment are accessible with high utility and enhanced precision. The said testing solutions are demanded in several industrial spheres, on account of their use, precision and simple to use design.

Send Inquiry

Send Inquiry